The printing industry, while essential, faces challenges regarding environmental impact and resource consumption. Traditional inks often rely on complex chemical processes that aren’t eco-friendly, and the constant replacement of ink cartridges raises concerns about waste. Researchers are exploring innovative alternatives, and a team from the Chinese Academy of Sciences has developed a promising solution: printing full-color images using transparent ink.

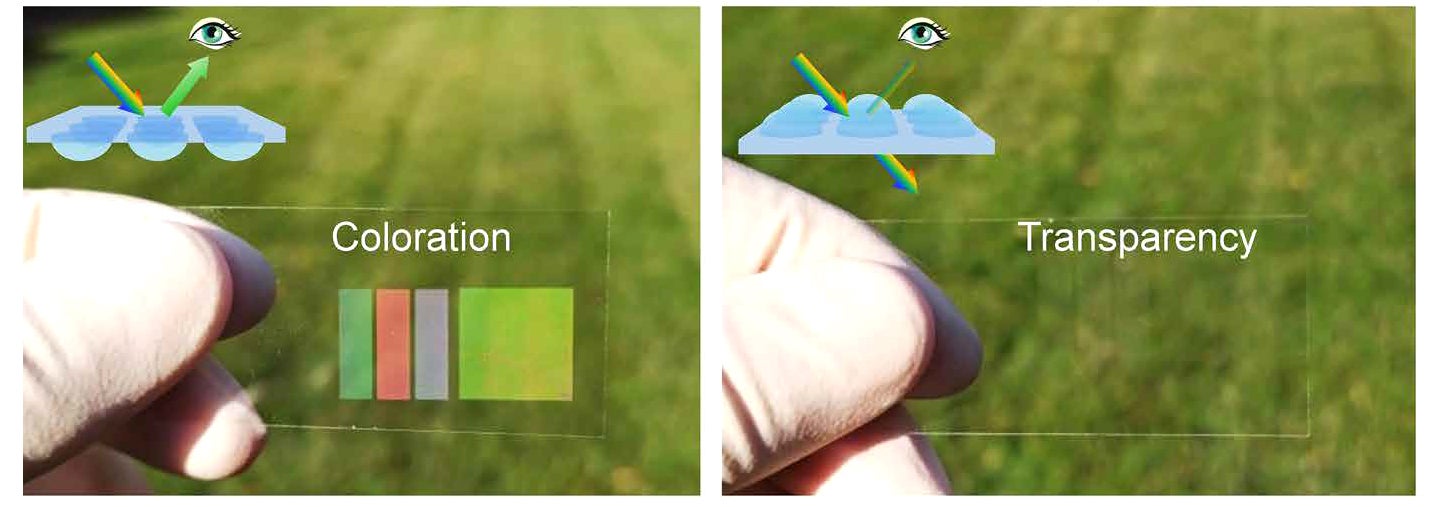

This groundbreaking approach leverages structural color, a phenomenon observed in nature where vibrant colors are produced by manipulating light reflection through microscopic structures. Instead of relying on pigments, this method utilizes a single, transparent polymer ink printed onto a hydrophobic glass surface.

How Does It Work?

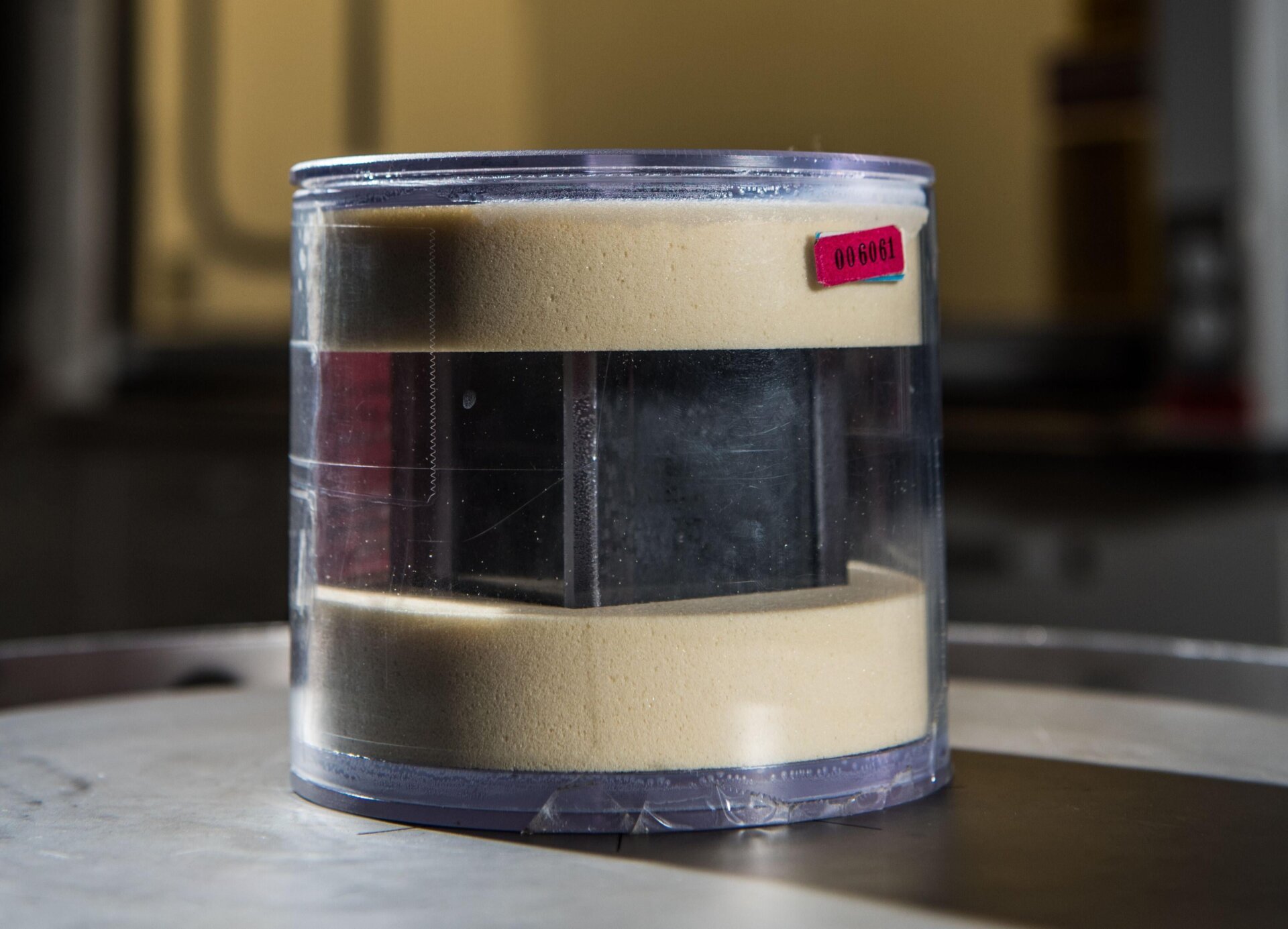

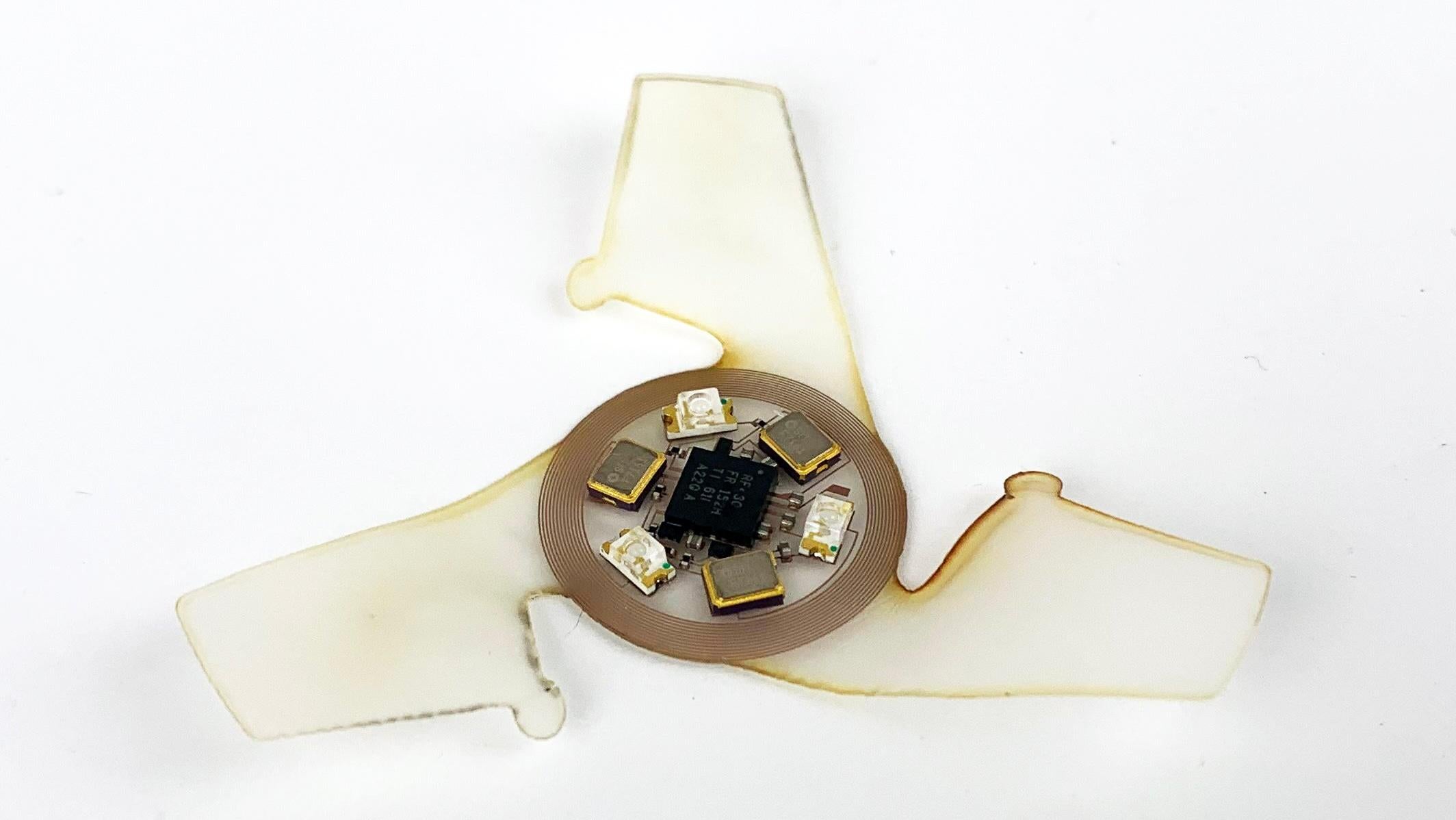

The process involves modifying an inkjet printer to dispense the transparent ink onto the specially treated glass. Due to the hydrophobic nature of the glass, the water-based ink droplets form tiny dome-like structures instead of spreading. These microdomes act as miniature lenses, reflecting different wavelengths of light based on their size and shape. The collective reflection of thousands of these microdomes creates a full-color image, similar to how colored pixels form an image on a screen.

Alt text: Microscopic domes of transparent ink on a glass surface, creating a structural color effect.

Alt text: Microscopic domes of transparent ink on a glass surface, creating a structural color effect.

This effect is unidirectional, meaning the image is visible only from one side of the glass. Viewed from the opposite side, the ink remains transparent. This unique characteristic opens up exciting possibilities, such as covering buildings with vibrant images without obstructing the view from within.

Advantages of Transparent Ink Printing

This innovative printing method offers several advantages over traditional ink-based printing:

- Compatibility with existing hardware: The process can be adapted to existing inkjet printers, including those used in commercial print shops.

- Reduced costs: Utilizing a single ink significantly reduces ink consumption and associated costs.

- Enhanced longevity: Structural colors are inherently more resistant to fading than traditional pigments, ensuring long-lasting prints.

- Environmental benefits: This method potentially reduces the environmental impact associated with traditional ink production and cartridge waste.

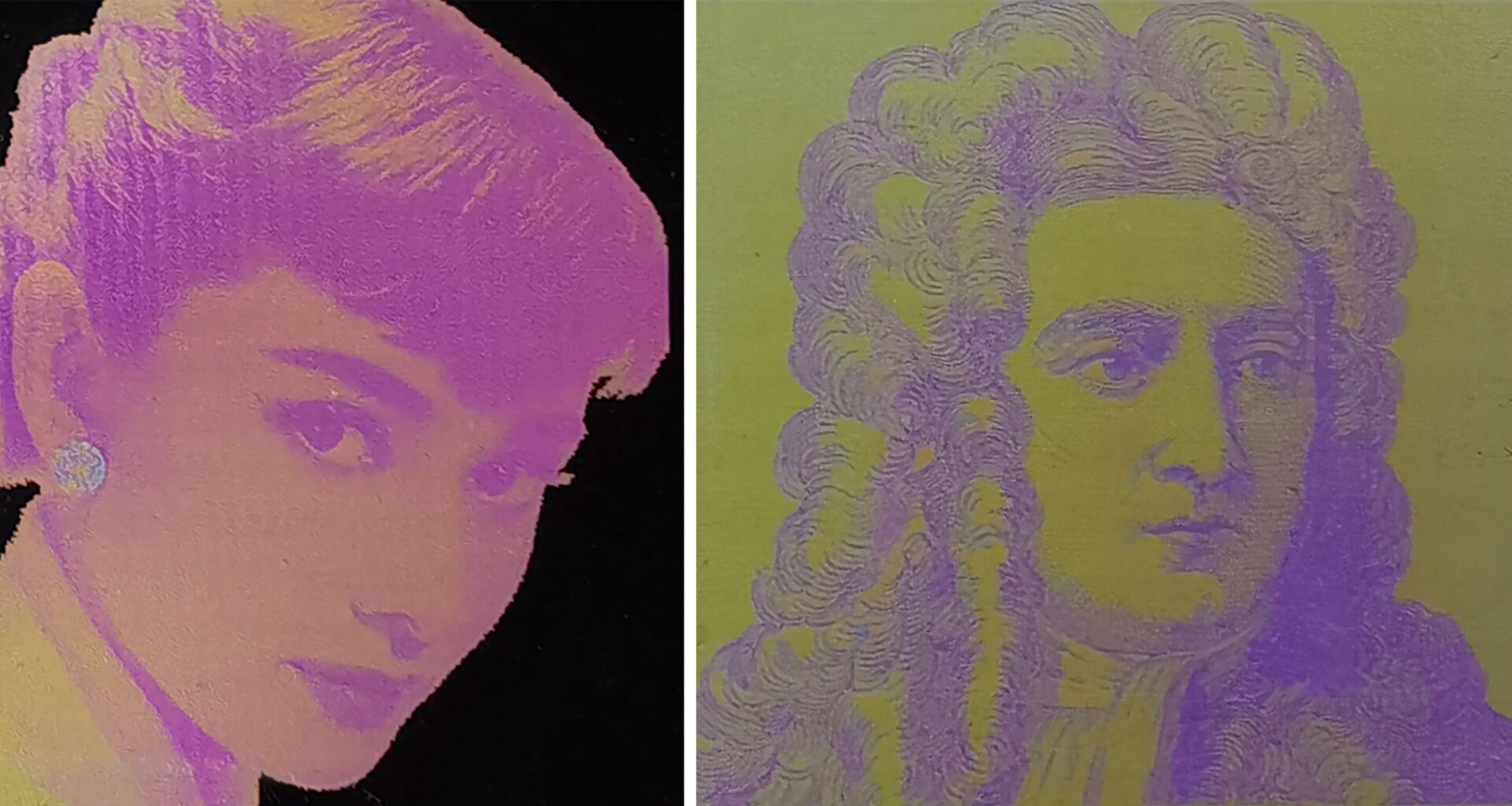

Alt text: Images of Audrey Hepburn and Isaac Newton printed using the transparent ink method, showcasing the detail and clarity achievable.

Alt text: Images of Audrey Hepburn and Isaac Newton printed using the transparent ink method, showcasing the detail and clarity achievable.

Future Potential

While the current focus is on recreating detailed images with limited color palettes, researchers believe they can achieve full control over color saturation and other aspects through precise manipulation of the microdome structures. This technology holds immense potential for various applications, from artistic displays and advertisements to architectural design and even bird-friendly window coverings.

The development of transparent ink printing represents a significant step towards a more sustainable and efficient printing industry. By harnessing the power of structural color, this innovative approach offers a vibrant and durable alternative to traditional printing methods, paving the way for exciting new possibilities in visual communication and design.