The quest for lightweight yet incredibly strong materials has taken a significant leap forward with the development of a groundbreaking two-dimensional (2D) polymer. This innovative material, resembling the interlocking links of chainmail, exhibits exceptional flexibility and strength, paving the way for potential applications in advanced protective gear like body armor and ballistic fabrics. Published in Science, the research spearheaded by Northwestern University scientists unveils a novel approach to material design with far-reaching implications.

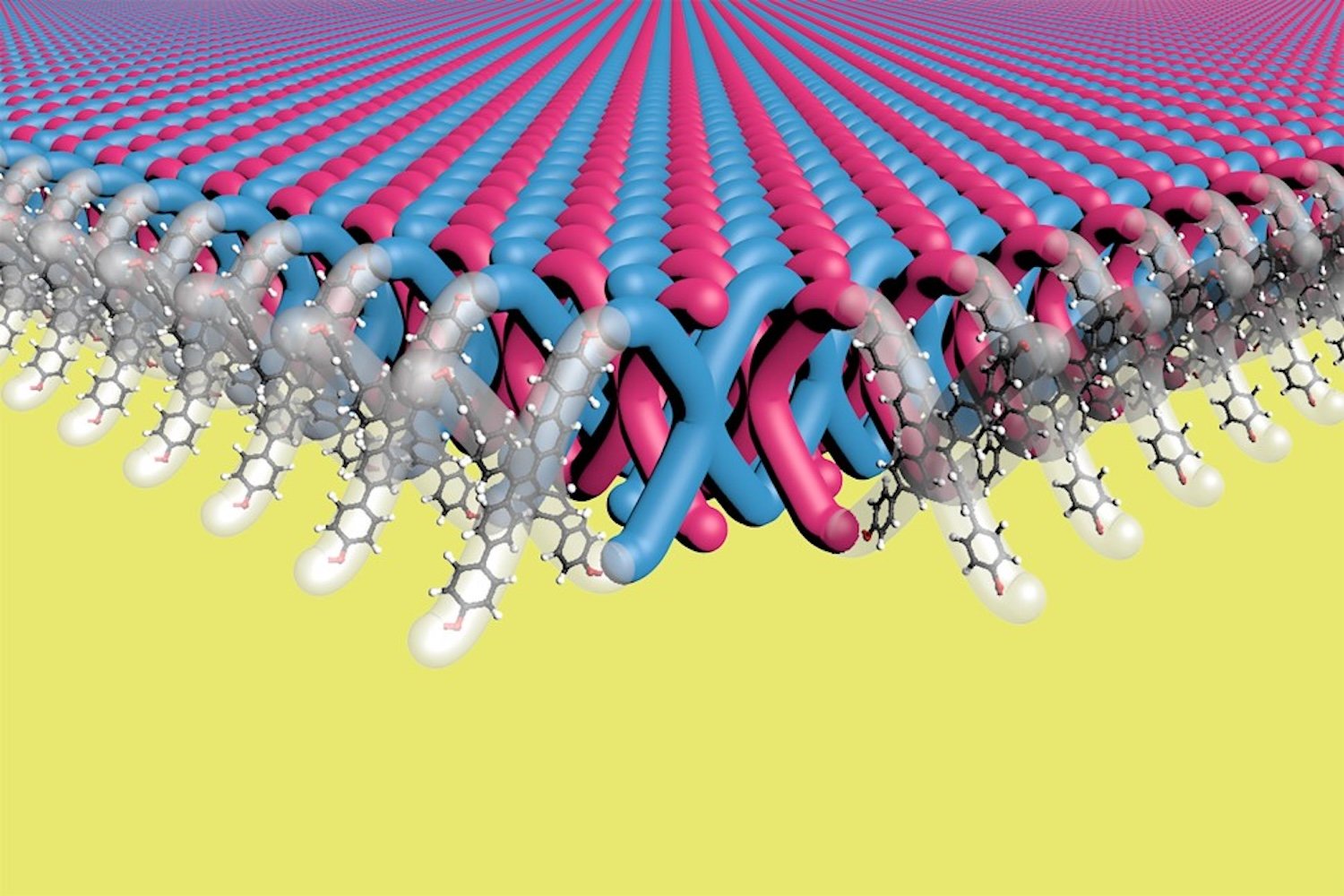

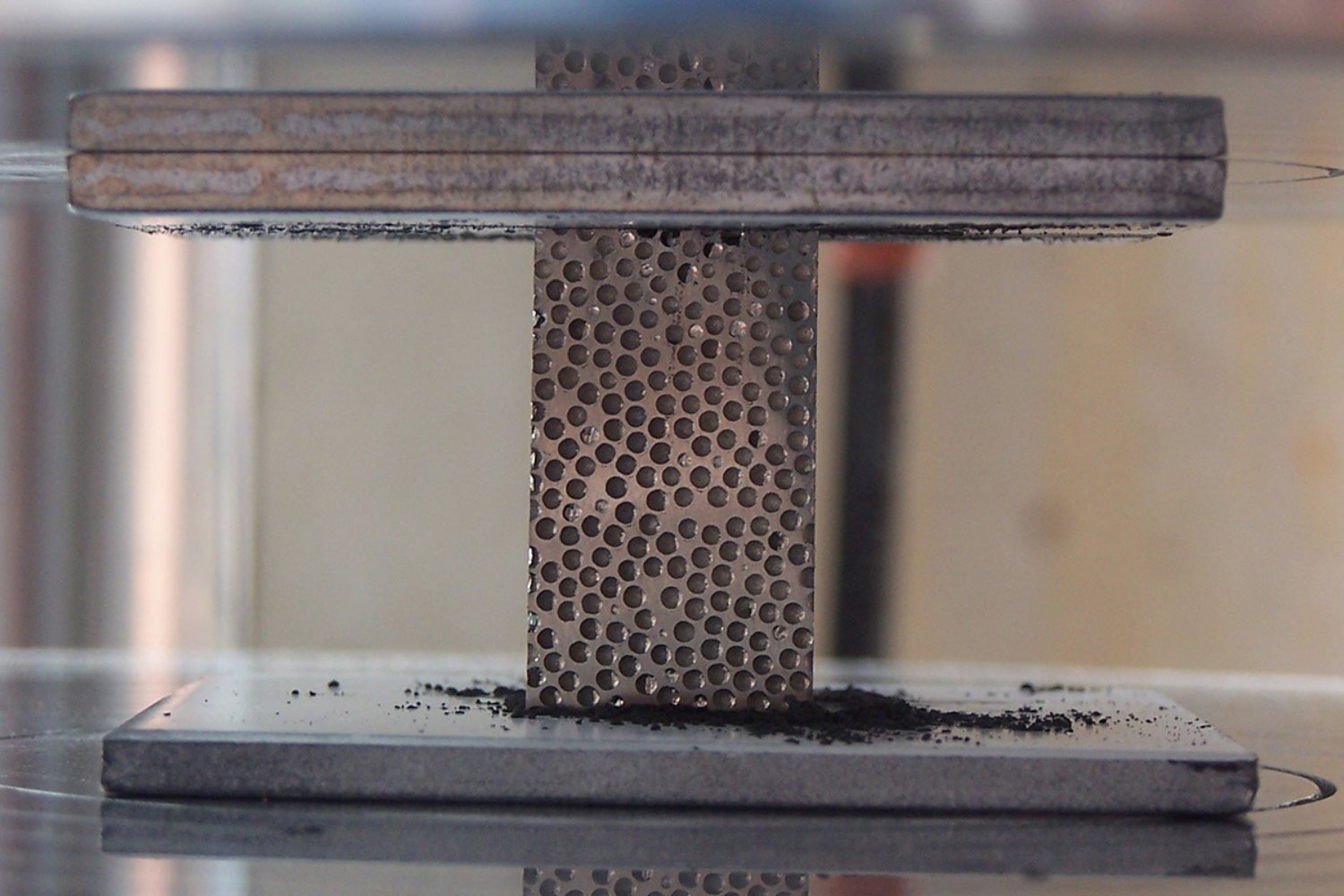

The breakthrough lies in the creation of a mechanically interlocked polymer structure at the nanoscale. Unlike conventional polymers that rely on covalent bonds (sharing of electrons), this material utilizes mechanical bonds, similar to the physical interlocking found in chainmail. This unique structure boasts an unprecedented density of 100 trillion mechanical bonds per square centimeter, contributing to its remarkable properties.

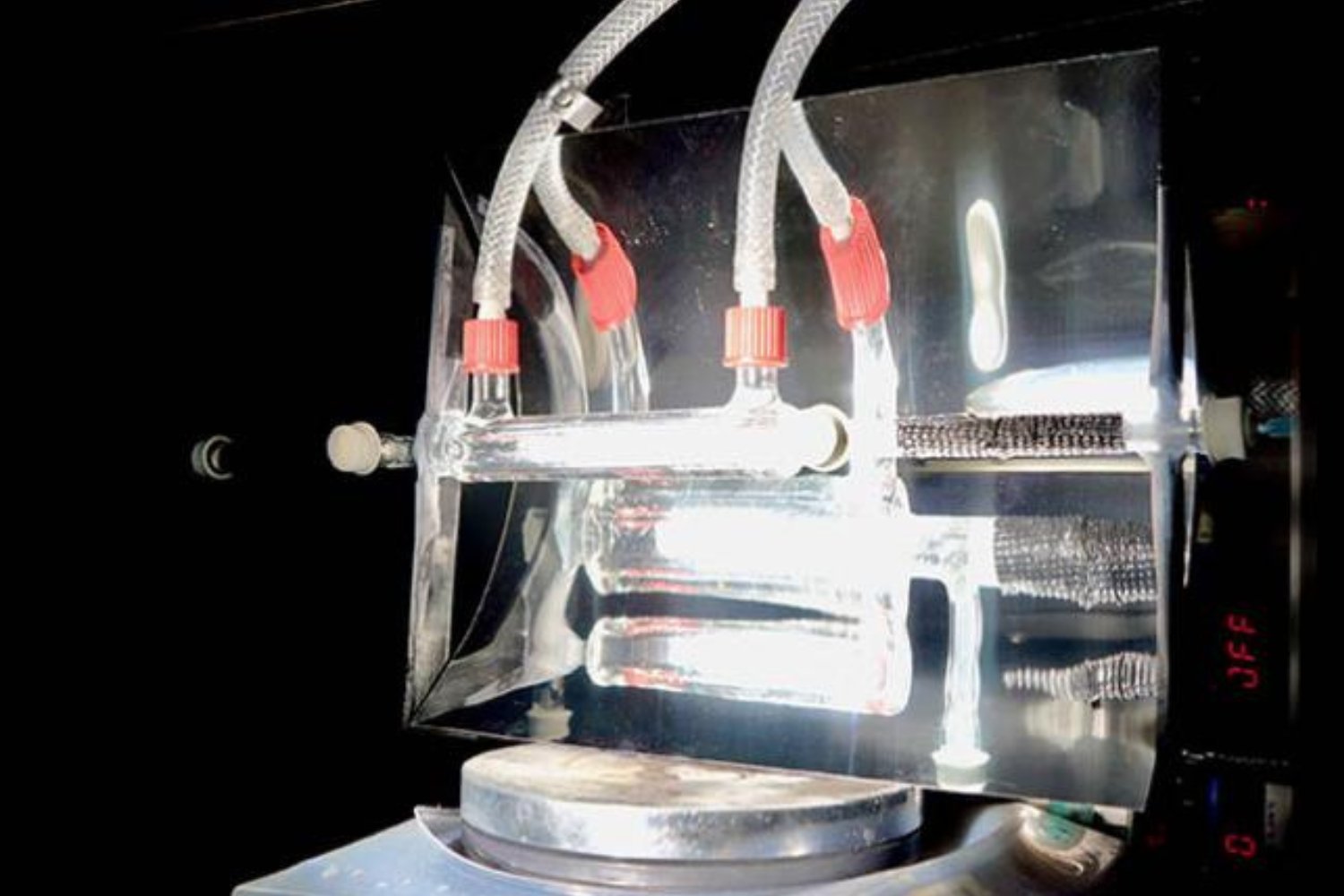

The key challenge in developing mechanically interlocked molecules has been guiding polymers to form these intricate bonds. The Northwestern team, led by Madison Bardot, devised an ingenious method involving the arrangement of X-shaped monomers into a crystalline structure, followed by a reaction with another molecule. This process generates mechanical bonds within the crystals, resulting in 2D layers of interlocked polymer sheets. These sheets, composed of interconnected X-shaped monomers, are further reinforced by filling the gaps with additional monomers.

This innovative approach represents a paradigm shift in polymer synthesis. As William Dichtel, a co-author of the study, explains, “We made a completely new polymer structure. It’s similar to chainmail in that it cannot easily rip because each of the mechanical bonds has a bit of freedom to slide around.” This inherent flexibility allows the material to dissipate applied force effectively, making it remarkably resistant to tearing. To rupture the material, numerous bonds would need to be broken simultaneously.

The 2D polymer’s unique structure also grants it remarkable solubility. When dissolved in a solvent, the individual sheets of interlocked molecules separate, allowing for easy manipulation and processing. This characteristic opens up exciting possibilities for tailoring the material’s properties for specific applications.

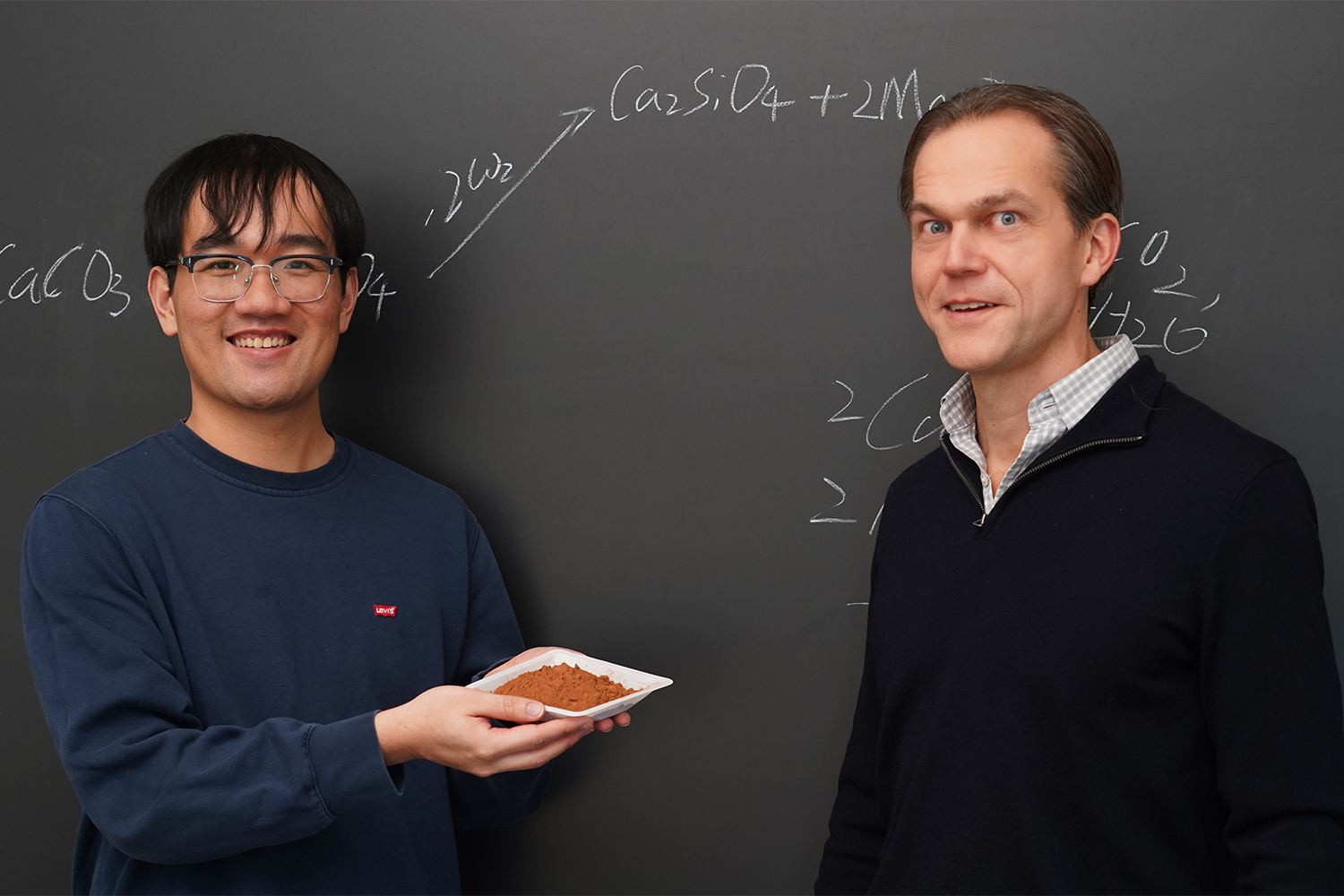

Previous attempts to create mechanically bonded polymers have yielded limited quantities, hindering scalability. However, the Northwestern team’s method has proven surprisingly scalable, producing over half a kilogram of the material. This achievement suggests the potential for large-scale production, making it a viable candidate for various industrial applications.

Furthermore, even small additions of the 2D polymer can significantly enhance the properties of other materials. The researchers demonstrated this by incorporating just 2.5% of the polymer into Ultem fiber (a high-performance material similar to Kevlar). The resulting composite exhibited a marked increase in strength, highlighting the potential of this novel polymer as a reinforcing agent.

This groundbreaking research marks a significant advance in material science. The exceptional strength, flexibility, and scalability of this 2D polymer hold immense promise for revolutionizing various industries. From protective gear to aerospace applications, this chainmail-inspired material may well be the foundation for the next generation of high-performance materials.