Of all the planet-warming greenhouse gases released by human activities, carbon dioxide (CO2) is the most significant. Experts advocate for both reducing fossil fuel use and actively removing CO2 from the atmosphere. However, existing carbon capture technologies are often expensive, energy-intensive, and require complex storage solutions. Researchers at Stanford University have proposed a surprisingly practical alternative: leveraging the natural CO2 absorption capabilities of rocks.

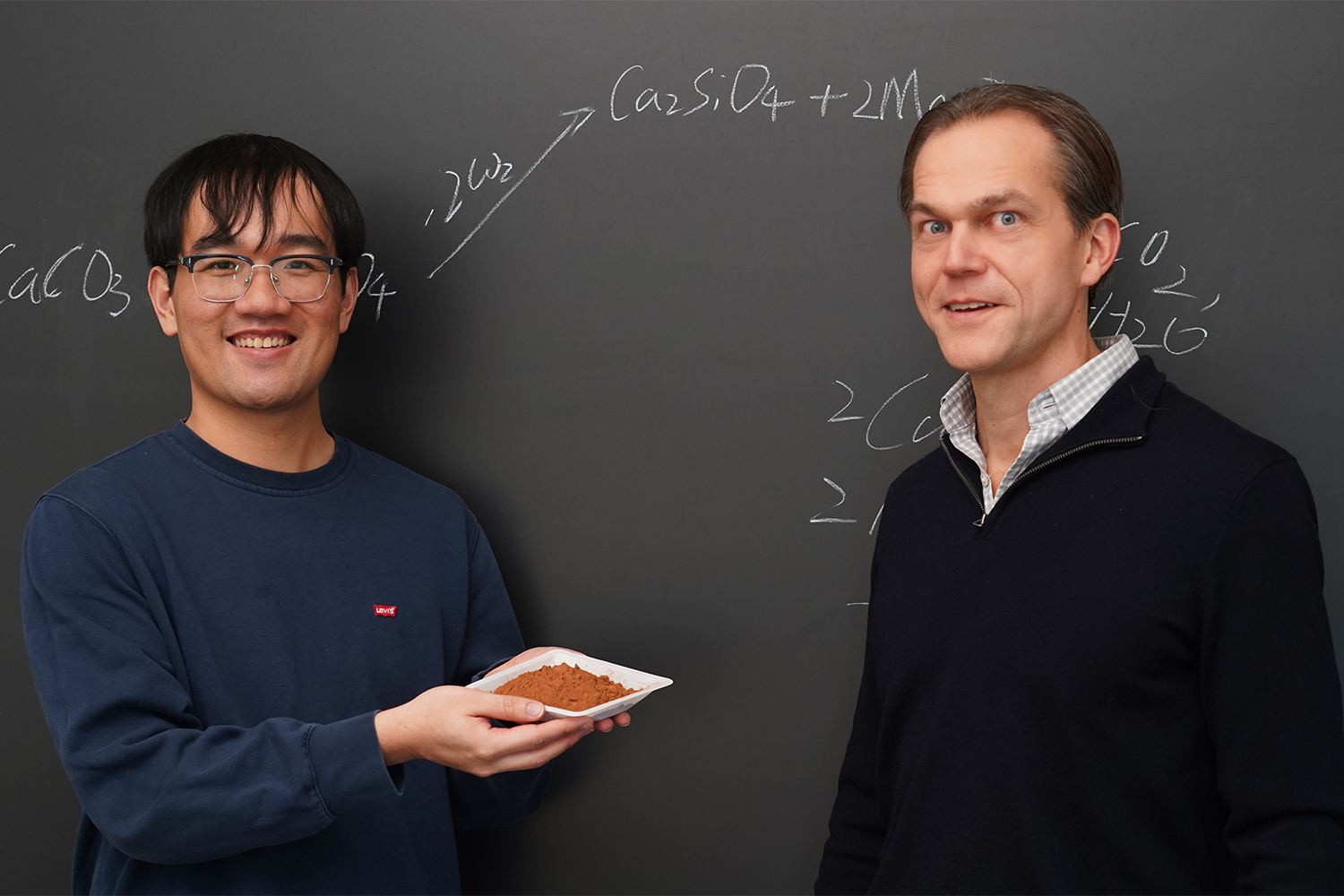

Stanford chemists Matthew Kanan and Yuxuan Chen have developed a process that uses heat to transform common minerals into efficient CO2 absorbers. Their research, published in Nature, details a practical and low-cost method that could also benefit agricultural practices, offering a dual-purpose solution.

“The Earth possesses a vast supply of minerals capable of removing CO2, but their natural reaction is too slow to offset human emissions,” explains Kanan. “Our work addresses this limitation with a uniquely scalable approach.”

Scientists have long explored ways to accelerate the natural CO2 absorption of rocks, a process known as weathering, which can take centuries or even millennia. Kanan and Chen appear to have found a solution by converting slow-weathering silicates into fast-weathering minerals.

“Our approach involves activating inert silicate minerals through a simple ion-exchange reaction,” explains Chen. “The effectiveness of this method exceeded our expectations.”

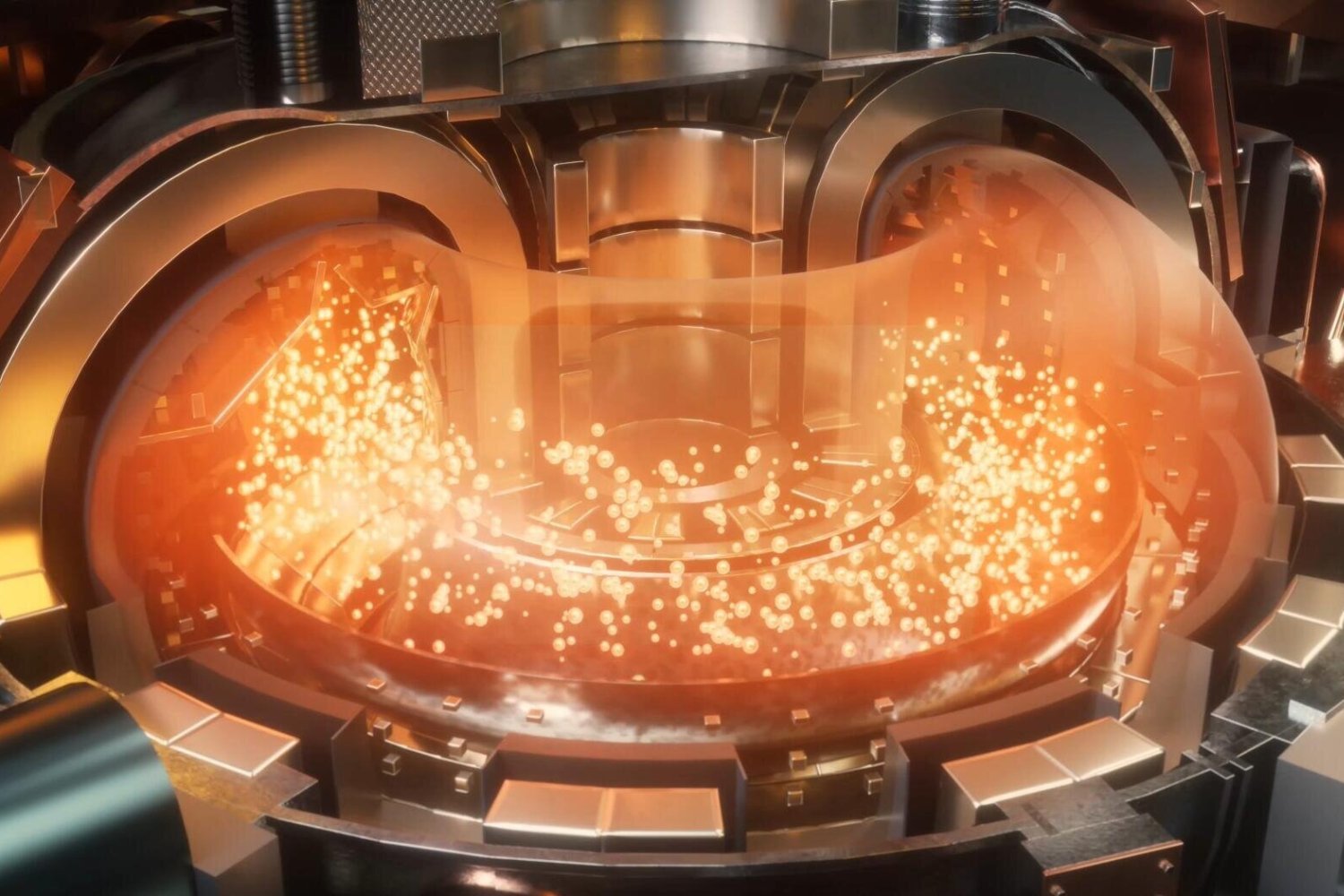

Inspired by cement production, where limestone is converted into reactive calcium oxide in a kiln, the chemists adapted this process, substituting sand with magnesium silicate. Heating the magnesium silicate causes an ion exchange, resulting in magnesium oxide and calcium silicate, both of which weather rapidly.

“This process acts as a multiplier,” Kanan states. “We start with one reactive mineral, calcium oxide, and a relatively inert magnesium silicate, and end up with two reactive minerals.”

In tests, the researchers exposed wet calcium silicate and magnesium oxide to air. Within weeks to months, they transformed into carbonate minerals, demonstrating the rapid weathering process.

“Imagine spreading these minerals over large areas to capture CO2 from the atmosphere,” Kanan suggests. “We’re currently exploring their application in agricultural soil.” This has practical implications for farmers, who often add calcium carbonate (lime) to counteract soil acidity.

“Our product could eliminate the need for traditional liming, as both mineral components are alkaline,” Kanan explains. “Furthermore, weathering calcium silicate releases silicon, which can enhance crop yields and resilience. Farmers would benefit from improved soil health and productivity, with carbon removal as an added bonus.”

Approximately one ton of the combined minerals can absorb one ton of CO2, even accounting for kiln emissions. This process requires less than half the energy of other carbon capture technologies.

Scaling this solution would require producing millions of tons of these minerals annually. However, Chen notes that estimated reserves of magnesium silicates like olivine and serpentine are potentially sufficient to remove all human-emitted atmospheric CO2. These silicates could also be sourced from mine tailings.

“Society already produces billions of tons of cement annually, and cement kilns operate for decades,” Kanan observes. “Leveraging this existing infrastructure and expertise provides a clear pathway for scaling our lab discovery to achieve meaningful carbon removal.”