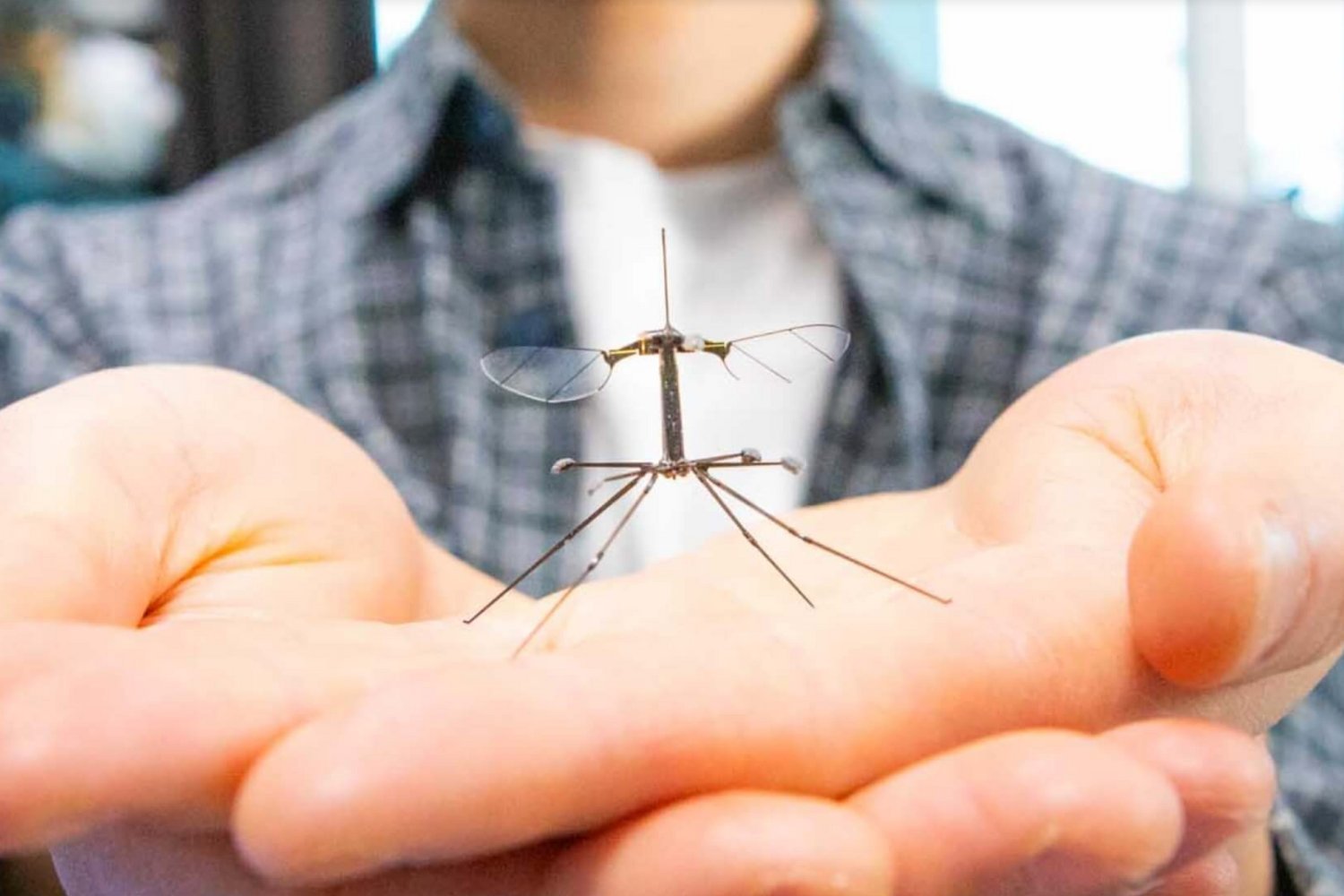

The Harvard Microrobotics Laboratory’s RoboBee, a miniature robot designed for tasks like pollination and environmental monitoring, has long faced a significant hurdle: landing. Previous iterations of the RoboBee could only manage crash landings, limiting its potential. Now, inspired by the crane fly, researchers have equipped the RoboBee with innovative landing gear, bringing it closer to real-world applications.

This advancement, detailed in a study published in Science Robotics, outlines how the RoboBee’s new landing system mimics the morphology of a crane fly. Four long, jointed legs, inspired by the crane fly’s own appendages, allow for softer, controlled landings. This crucial upgrade addresses a long-standing challenge for the tiny robot and opens doors to a range of potential uses, from environmental monitoring and disaster surveillance to artificial pollination and even delicate biological manipulations.

A Bio-Inspired Solution

The RoboBee’s design team, led by Harvard professor Robert Wood, turned to the university’s Museum of Comparative Zoology for inspiration. After exploring various biological models, they settled on the crane fly’s unique leg structure. These insects, often mistaken for giant mosquitoes, possess long, flexible legs ideal for absorbing impact. By incorporating similar appendages into the RoboBee’s design, the team successfully achieved gentler landings, described as a “gentle plop-down.” This new design also includes an improved controller, essentially the robot’s brain, which helps decelerate the RoboBee during its landing approach.

Robobee Progression

Robobee Progression

Overcoming the “Ground Effect”

Prior versions of the RoboBee struggled with controlled landings due to “ground effect.” This phenomenon, also experienced by helicopters, is caused by air vortices generated by the flapping wings, creating instability near the ground. The RoboBee’s small size, weighing just 0.004 ounces (1/10th of a gram) with a 1.2-inch (3 centimeter) wingspan, makes this effect even more pronounced. The new legs, combined with the enhanced controller, mitigate this issue, enabling stable descents. Nak-seung Patrick Hyun, a former Harvard postdoctoral fellow and now an assistant professor at Purdue University, explains that successful landings depend on minimizing velocity before impact and quickly dissipating energy upon touchdown. Hyun led the RoboBee’s landing tests on both solid surfaces and leaves.

Leaf Landing Composite

Leaf Landing Composite

Protecting Delicate Components

The crane fly-inspired legs also provide crucial protection for the RoboBee’s delicate piezoelectric actuators. These actuators function like the robot’s muscles and are vulnerable to damage from impacts. The compliant legs act as shock absorbers, safeguarding these components during landings. This added protection is essential for extending the lifespan and operational reliability of the RoboBee.

The Future of RoboBee

The research team’s next objective is to equip the RoboBee with autonomous sensor capabilities, onboard power, and enhanced control systems. These advancements are seen as crucial for realizing the RoboBee’s full potential and bringing its envisioned applications closer to reality. By achieving these goals, the RoboBee could revolutionize various fields, offering new possibilities for environmental monitoring, disaster relief, and even agricultural practices.