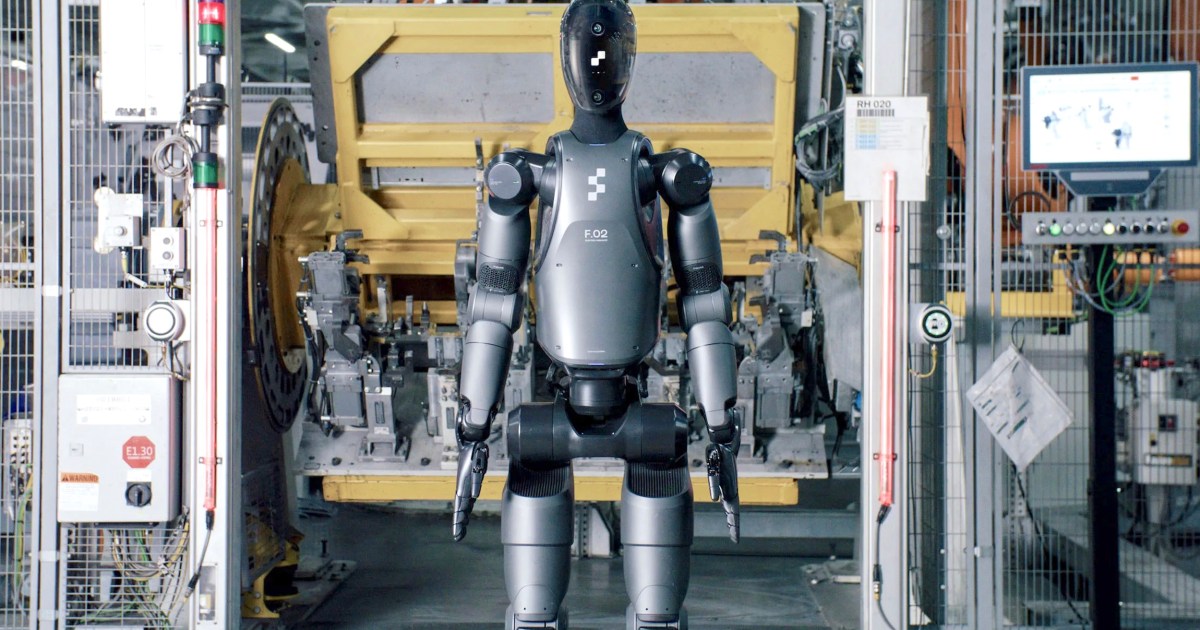

Figure, a robotics startup, recently showcased its Figure 02 humanoid robot performing a crucial automotive task. This demonstration, part of a trial deployment at BMW’s Spartanburg, South Carolina plant, highlights the potential of humanoid robots to revolutionize the automotive industry.

Figure’s video demonstrates the robot’s capability to insert sheet metal parts into fixtures for vehicle chassis assembly. The company claims the fully autonomous robot can achieve 1,000 placements daily, with the latest version boasting improved accuracy and speed. This trial offers a glimpse into a future where humanoid robots could play a significant role in automotive manufacturing.

BMW acknowledged the promising developments in robotics following the trial in August, stating, “With an early test operation, we are now determining possible applications for humanoid robots in production.” The company highlighted the potential for these robots to relieve human workers from ergonomically challenging and repetitive tasks. The trial also provided BMW with valuable insights into integrating multi-purpose robots into their existing production system.

The collaboration between BMW and Figure aims to further refine the robot’s design and prepare it for broader applications in auto manufacturing. This partnership underscores the growing interest in exploring the potential of humanoid robots in industrial settings.

Figure unveiled its latest humanoid robot model in August, coinciding with the BMW trial. This upgraded version features triple the processing power of its predecessor, enhanced voice communication, improved cameras, microphones, and sensors, and a high-performance battery. Crucially, it also features fourth-generation human-scale hands with 16 degrees of freedom and human-equivalent strength. These advanced hands are designed for complex two-handed tasks requiring varied and dynamic manipulation, intricate grasping, and precise coordination.

While advanced multi-axis robotic arms have been a mainstay in car plants for decades, humanoid robots offer potential advantages in versatility and adaptability. This flexibility is particularly valuable in dynamic manufacturing environments. The dexterity of humanoid robot hands is also expected to improve, enabling them to perform more delicate tasks currently beyond the capabilities of traditional industrial robots. Furthermore, advancements in AI promise to enhance cognitive abilities, allowing for greater autonomy and intelligent action.

Multi-axis robots excel at specific, repetitive tasks, but humanoid robots present a more flexible solution for complex, varied environments where human-like interaction and problem-solving are essential. While the current generation of humanoid robots is still in development, demonstrations like Figure’s showcase the rapid progress being made in this field.