Humanoid robots are rapidly advancing, attracting the attention of major companies like Mercedes-Benz. The German auto giant recently partnered with Apptronik, a Texas-based robotics company, to explore using advanced humanoid robots in its manufacturing facilities. The collaboration will involve a trial run of Apptronik’s Apollo robot working alongside human employees on the factory floor.

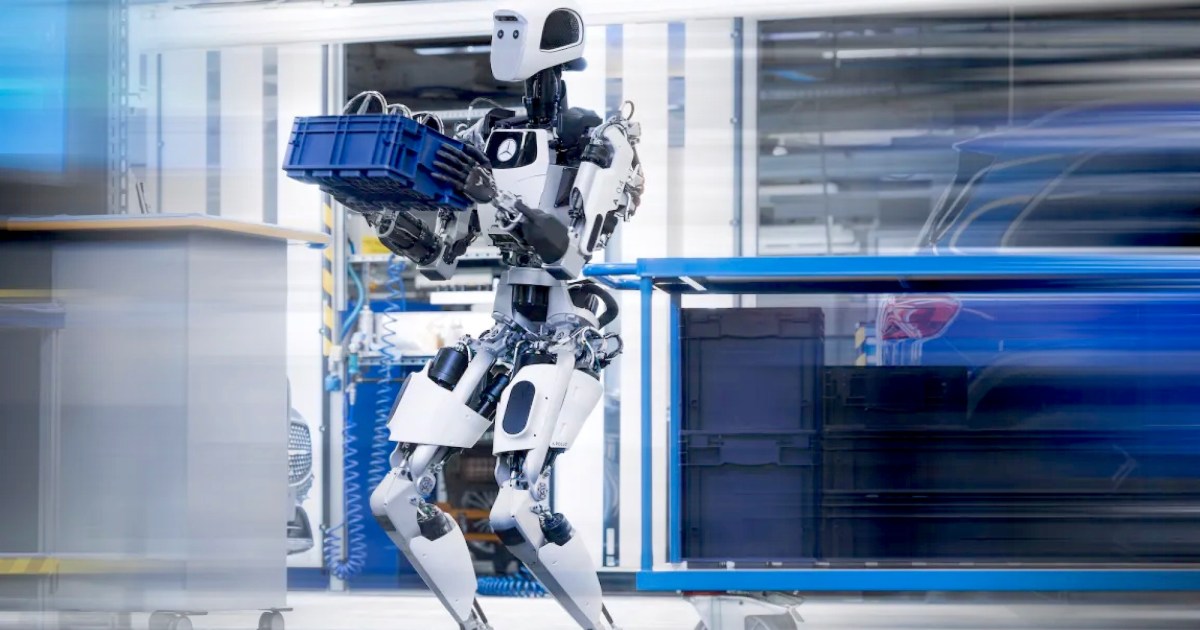

ApptronikApptronik’s Apollo humanoid robot is being trialled by Mercedes-Benz in its manufacturing facilities.

ApptronikApptronik’s Apollo humanoid robot is being trialled by Mercedes-Benz in its manufacturing facilities.

Apollo’s Role in Mercedes-Benz Factories

During the trial, Apollo will transport vehicle parts to the production line for assembly and deliver totes of kitted parts later in the manufacturing process. This collaboration represents a significant step for Apptronik, as highlighted by Jeff Cardenas, co-founder and CEO: “When we set out to build Apollo, an agreement like the one we’re announcing today with Mercedes-Benz was a dream scenario.” He further emphasized the robot’s potential to automate low-skill, physically demanding tasks, predicting similar implementations by other organizations in the future.

Addressing Labor Gaps and Enhancing Efficiency

The introduction of humanoid robots in the workplace often raises concerns about job displacement. However, both Apptronik and Mercedes-Benz emphasize the robots’ assistive role rather than replacing human workers. Mercedes executive Jörg Burzer explains that the goal is to address labor shortages in areas involving repetitive and physically demanding tasks, allowing highly skilled employees to focus on more complex responsibilities.

Apollo: A culmination of Apptronik’s Robotics Expertise

Apollo represents the culmination of Apptronik’s extensive experience in robotics, including their work on NASA’s Valkyrie humanoid robot. Standing at 5 foot 8 inches and weighing 160 pounds, Apollo can handle payloads up to 55 pounds and operate for four hours on a single charge, with swappable batteries for continuous operation.

The Rise of Humanoid Robots in the Auto Industry

Apptronik is not alone in developing humanoid robots for the automotive sector. Figure, a California-based company, partnered with BMW to deploy its humanoid robot at a plant in South Carolina. Tesla is developing its Optimus bipedal robot, Xiaomi is working on CyberOne, and Boston Dynamics continues its research on versatile robots for various workplace applications.

Conclusion: A Collaborative Future for Humans and Robots

The partnership between Mercedes-Benz and Apptronik highlights the growing trend of integrating humanoid robots into industrial settings. By automating physically demanding and repetitive tasks, these robots can address labor shortages, improve efficiency, and allow human workers to focus on more skilled and engaging roles. This collaborative approach suggests a future where humans and robots work together to optimize productivity and enhance overall workplace dynamics.