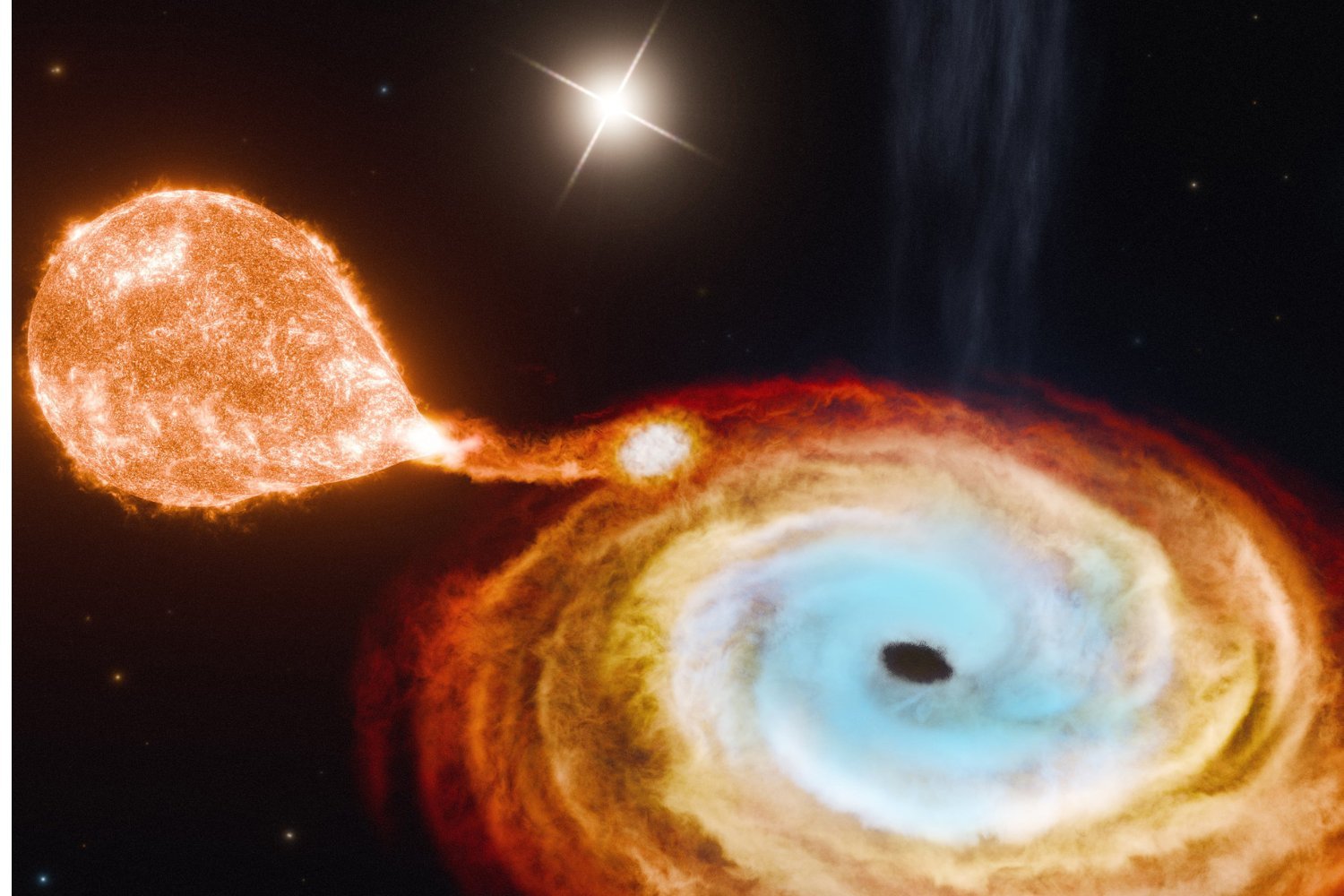

The ambition to establish human settlements on the Moon and Mars necessitates innovative construction techniques. Instead of relying on traditional methods, NASA is investigating the potential of laser beam welding to revolutionize in-space manufacturing, paving the way for more durable and sustainable lunar habitats.

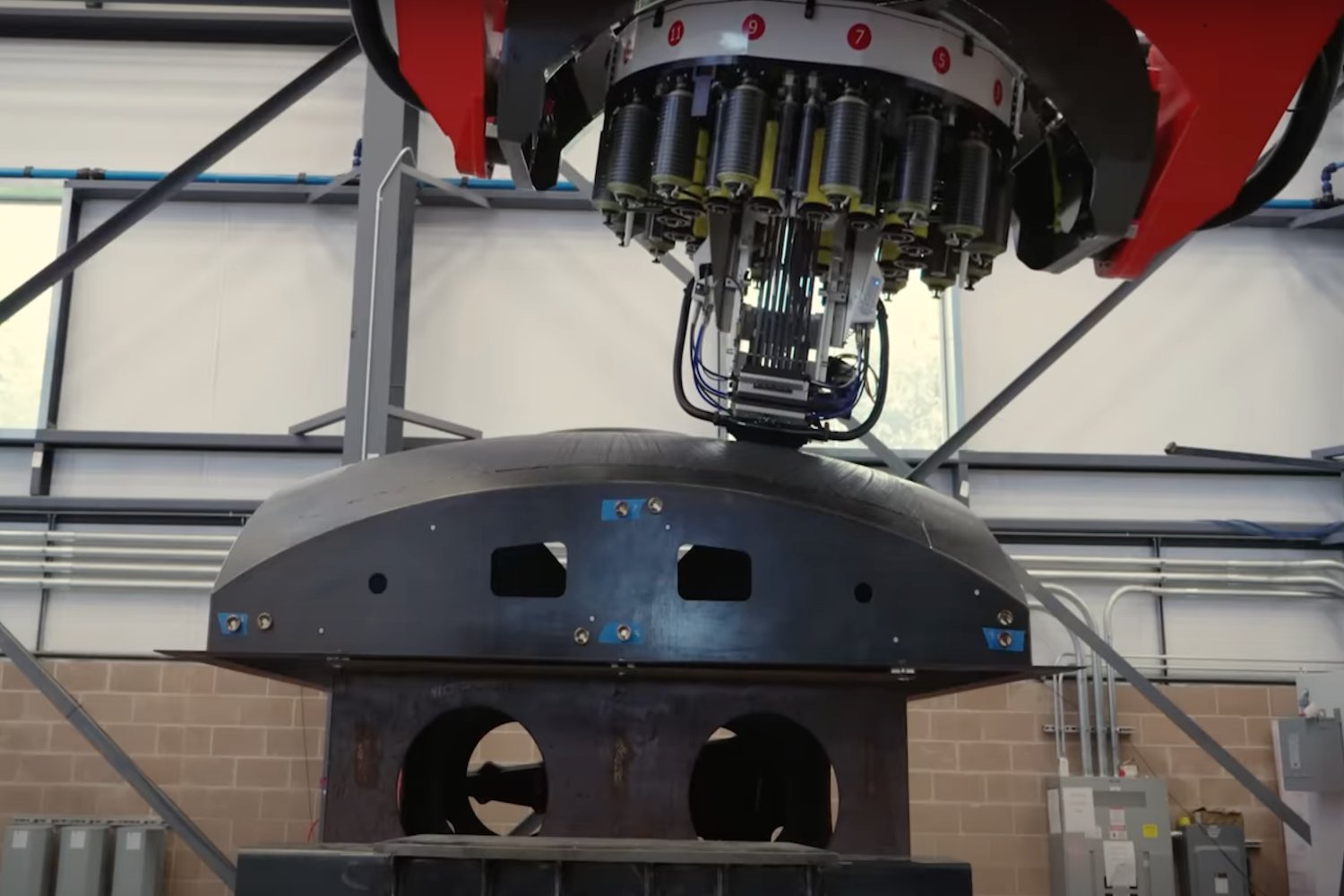

This groundbreaking research, a collaborative effort between NASA’s Marshall Space Flight Center and Ohio State University, aims to test the efficacy of laser beam welding in the unique conditions of vacuum and reduced gravity. Traditional construction methods, relying on fasteners and rivets, present limitations for creating robust structures in space. “For a long time, we’ve used fasteners, rivets, or other mechanical means to keep structures that we assemble together in space,” explains Andrew O’Connor, NASA’s technical lead for the project. “But we’re starting to realize that if we really want strong joints and if we want structures to stay together when assembled on the lunar surface, we may need in-space welding.”

Laser beam welding offers the potential to construct large structures, manufacture new components, and repair damage on the Moon, significantly reducing the need for costly and complex cargo missions to transport materials. However, understanding how welds behave in the microgravity environment of space is crucial. “Once you leave Earth, it becomes more difficult to test how the weld performs, so we are leveraging both experiments and computer modeling to predict welding in space while we’re still on the ground,” O’Connor adds.

Initial tests commenced in August, with high-powered fiber laser beam welding experiments conducted in simulated reduced gravity aboard a commercial aircraft. Parabolic flight maneuvers, involving climbing 8,000 feet and then descending in a parabolic arc, created brief periods of reduced gravity, approximately 20 seconds each, mimicking the conditions of space. During these weightless intervals, the team performed simulated in-space welding, with a network of sensors meticulously collecting data to analyze the impact of the unique environment on the welding process. Will McAuley, an Ohio State welding engineering student, reported a remarkable success rate, stating, “During the flights we successfully completed 69 out of 70 welds in microgravity and lunar gravity conditions, realizing a fully successful flight campaign.”

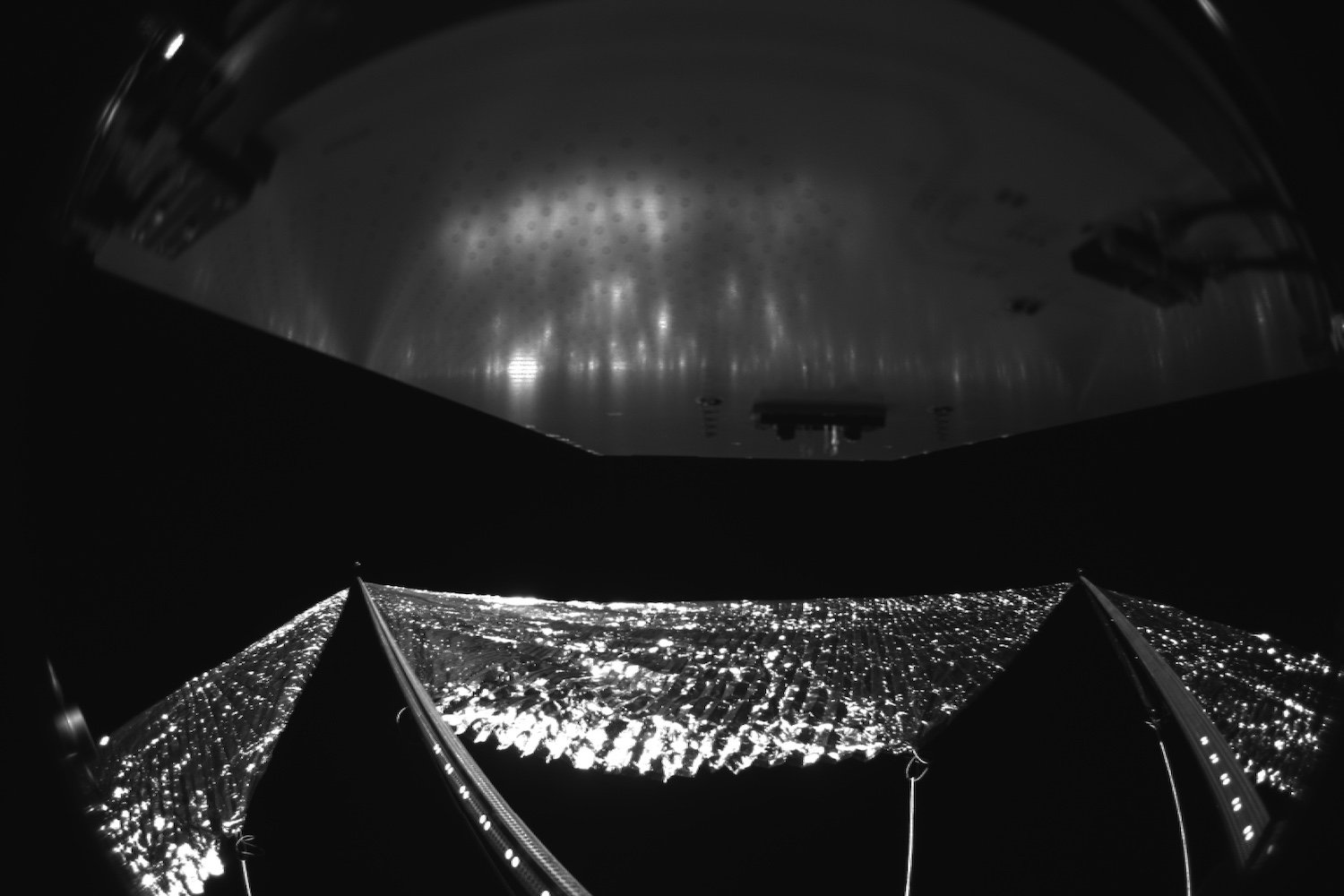

These experiments mark a significant return to in-space welding research for NASA, a field largely unexplored since the bead-on-plate welding, brazing, and metal melting experiments conducted aboard the Skylab orbital space station in 1973. This renewed focus on in-space manufacturing is timely, aligning with NASA’s ambitions for establishing a sustainable human presence on the Moon and potentially Mars in the future. In-space welding offers the promise of streamlined construction and repair capabilities, reducing reliance on Earth-based resources.

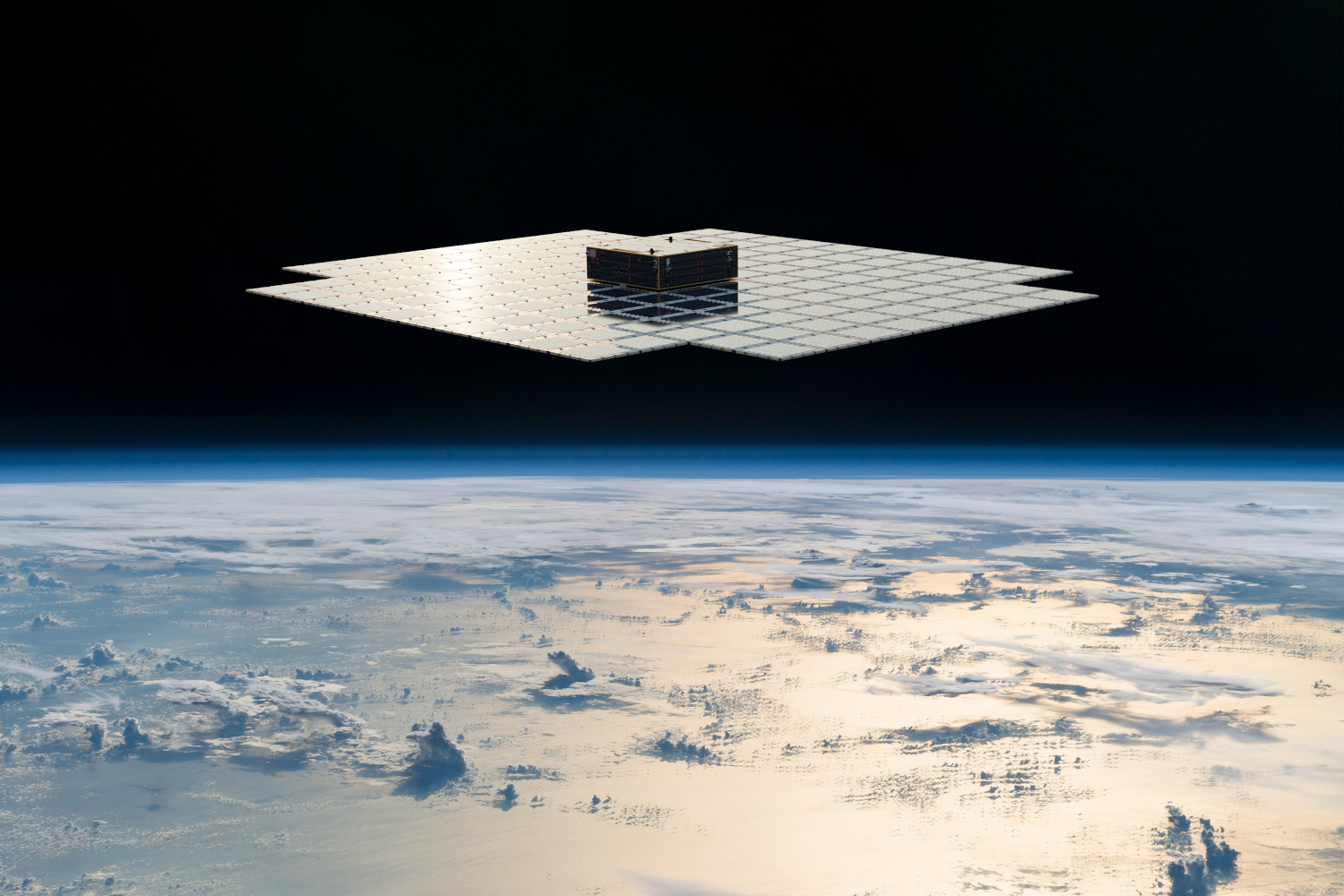

Furthering this research, the Nanoracks Astrobeat experiment, launched to the International Space Station (ISS) aboard the 31st resupply mission, is exploring cold welding as a method for repairing spacecraft damage caused by micrometeorites and space debris. This approach offers the potential for safer and more efficient in-space repairs conducted from within the spacecraft.

In conclusion, NASA’s exploration of laser beam welding represents a pivotal step towards realizing the dream of sustainable human settlements beyond Earth. This innovative technology promises to transform in-space construction, enabling the creation of durable lunar habitats and facilitating future exploration endeavors.