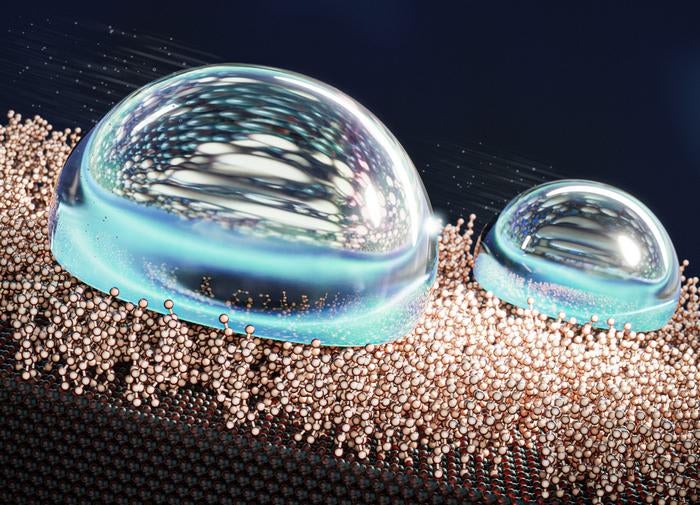

Water’s tendency to bead and slide isn’t limited to a duck’s back. Scientists have pioneered a novel method for coating surfaces with a liquid-like layer, rendering them exceptionally slick.

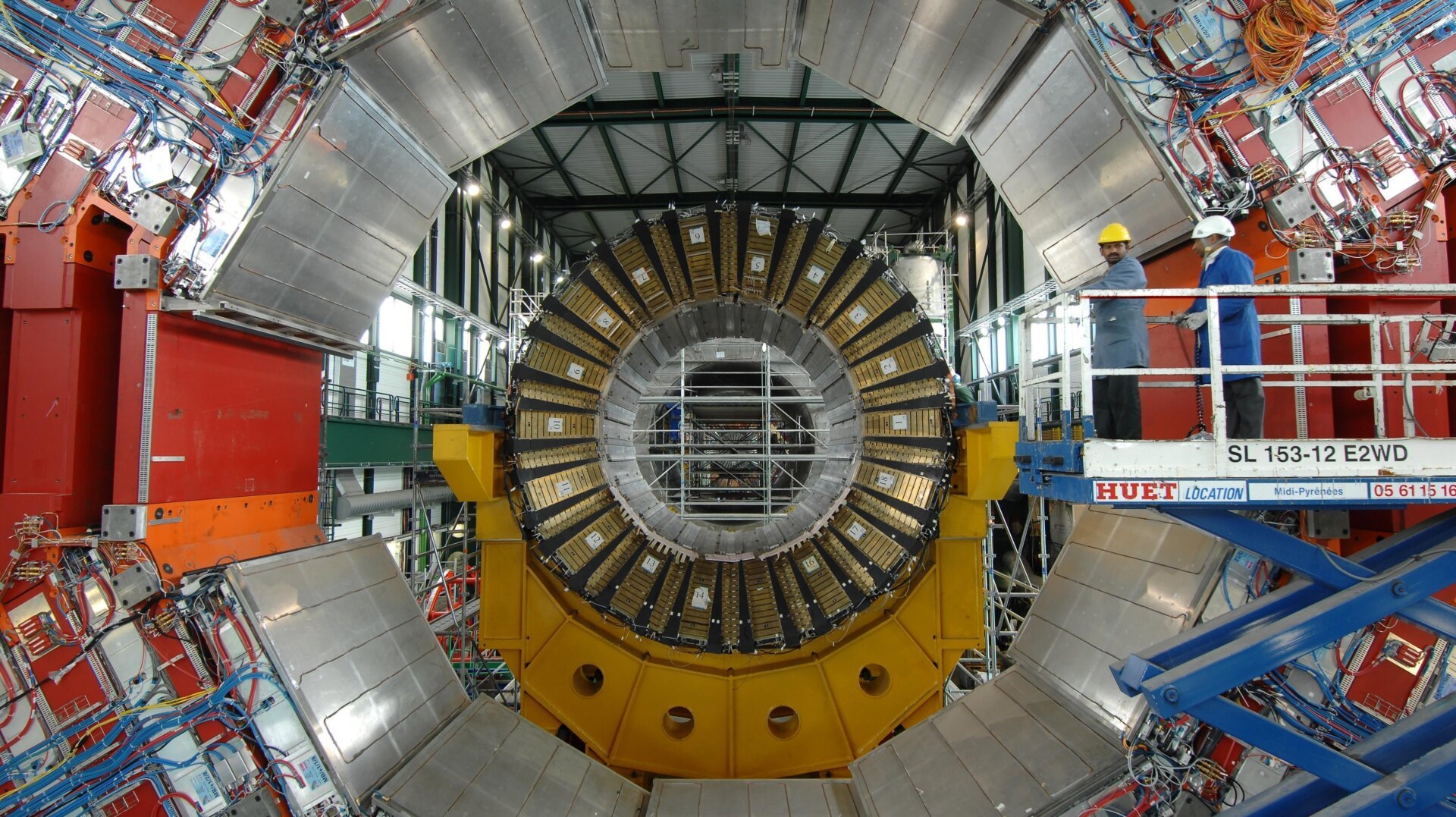

A Finland-based research team, spearheaded by Sakari Lepikko of Aalto University, has developed a specialized reactor to create these unique surfaces, known as self-assembled monolayers (SAMs). These monolayers exhibit a fluid-like characteristic due to layers of molecules covalently bonded to silicon, mirroring the way liquid molecules interact.

This innovative approach drastically reduces surface friction, enabling water droplets to glide effortlessly. The researchers claim this manufacturing process is the first of its kind. Their groundbreaking research is detailed in a paper published in Nature Chemistry.

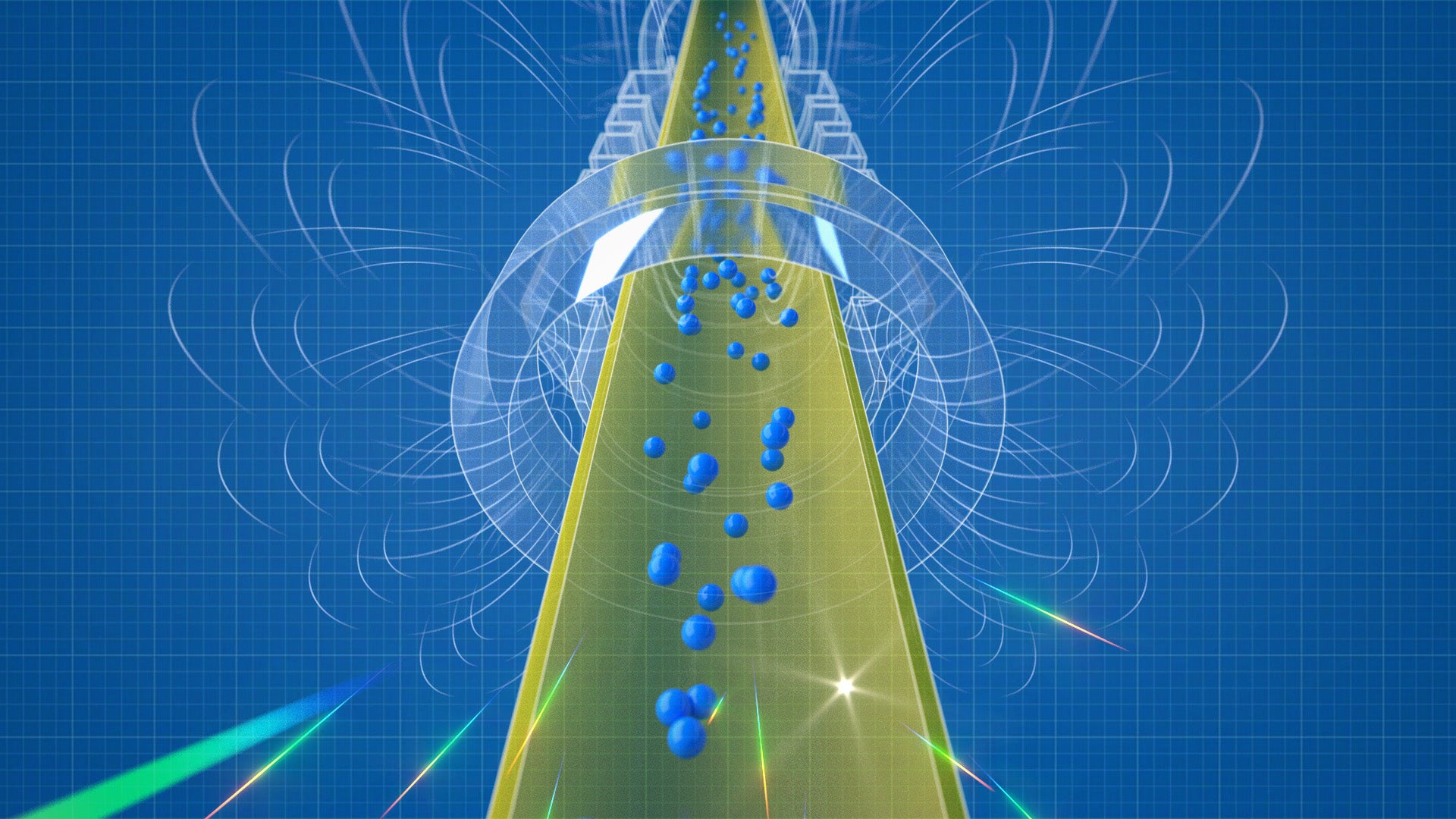

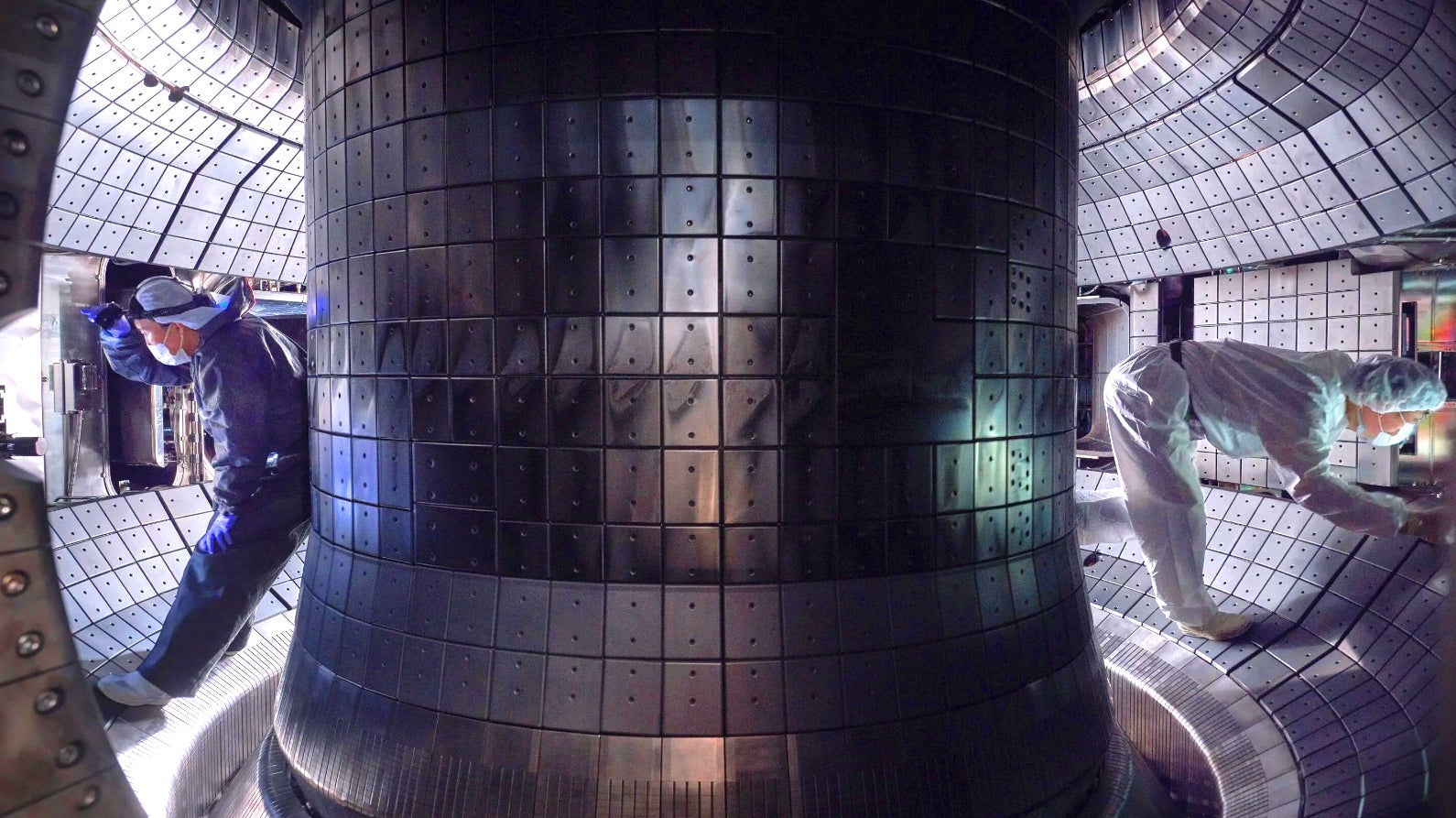

Droplets on an engineered surface.Microscopic view of water droplets resting on the engineered SAM surface. Image: Ekaterina Osmekhina/Aalto University

Droplets on an engineered surface.Microscopic view of water droplets resting on the engineered SAM surface. Image: Ekaterina Osmekhina/Aalto University

Nanoscale Engineering for Ultra-Slippery Surfaces

“Our work represents the first instance of directly manipulating materials at the nanometer scale to create molecularly heterogeneous surfaces,” Lepikko explained in a press release. “A key challenge with SAM coatings is their thinness, making them susceptible to dispersion after physical contact. However, studying them provides fundamental scientific knowledge that we can leverage to develop durable, practical applications.”

Vapor Deposition: The Key to Creating Liquid-Like Surfaces

Lepikko and his team employed a vapor deposition reactor – a device that deposits thin material layers onto surfaces through vapor condensation – to fabricate the SAMs. Specifically, the process involved spraying a silicon surface with octyltrichlorosilane to create the liquid-like coating. By adjusting the silicon’s exposure time within the reactor, the researchers could control the SAM’s slipperiness.

Surprising Results: Less is More (and More is More)

Testing revealed a surprising outcome: both short (approximately 30 seconds) and long (upwards of four hours) growth times yielded the slickest surfaces, surpassing intermediate durations. Short growth times caused water droplets to spread, while longer durations led to more pronounced beading.

The Science of Slipperiness: Homogeneity is Key

“The results demonstrated increased slipperiness with low or high SAM coverage, corresponding to the most homogeneous surface states,” Lepikko stated. “Counterintuitively, even low coverage produced exceptional slipperiness.”

From Lab to Life: Practical Applications of Ultra-Slippery Coatings

While the pursuit of slipperiness might seem trivial, this research holds significant practical implications. In 2016, Penn State University researchers developed a 2.5-micron thick coating inspired by plant wax, allowing viscous fluids like ketchup and mustard to slide off surfaces. Lepikko highlights potential applications for their SAMs, including de-icing, anti-fogging, and self-cleaning surfaces.

The Future of Slick Surfaces

This innovative research opens exciting possibilities for diverse applications, from enhancing everyday products to developing advanced materials with unique properties. The ability to control surface slipperiness at the nanoscale offers a powerful tool for engineers and scientists across various disciplines.