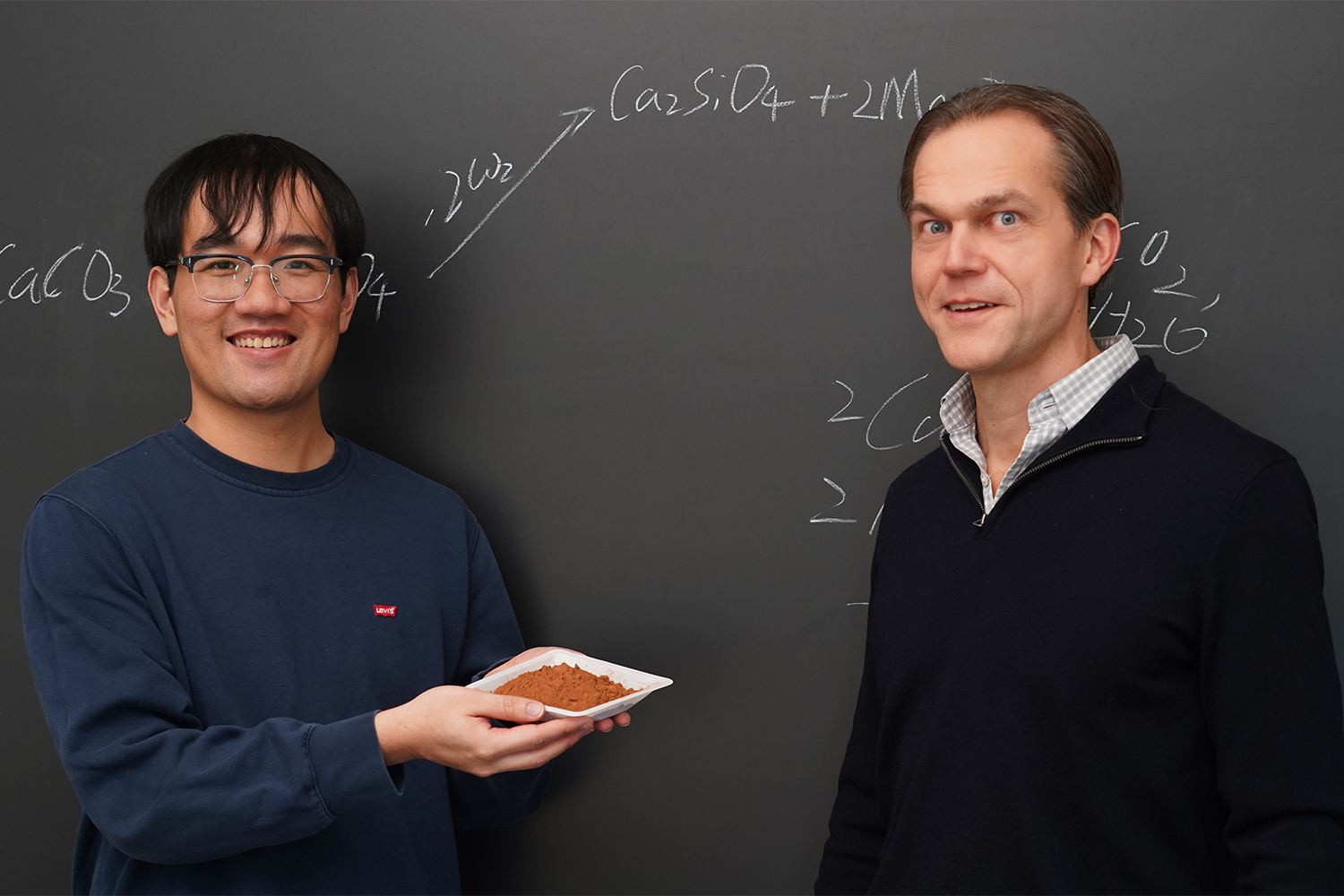

Composite Metal Foam (CMF) is a revolutionary material boasting the strength of steel, the lightness of aluminum, and remarkable resistance to ballistic impacts, fire, and radiation. Developed by engineer Afsaneh Rabiei at North Carolina State University, this innovative material is poised to transform industries ranging from aerospace and defense to automotive and nuclear energy. But what exactly is CMF, and how does it achieve such impressive properties?

The Science Behind CMF’s Strength and Lightness

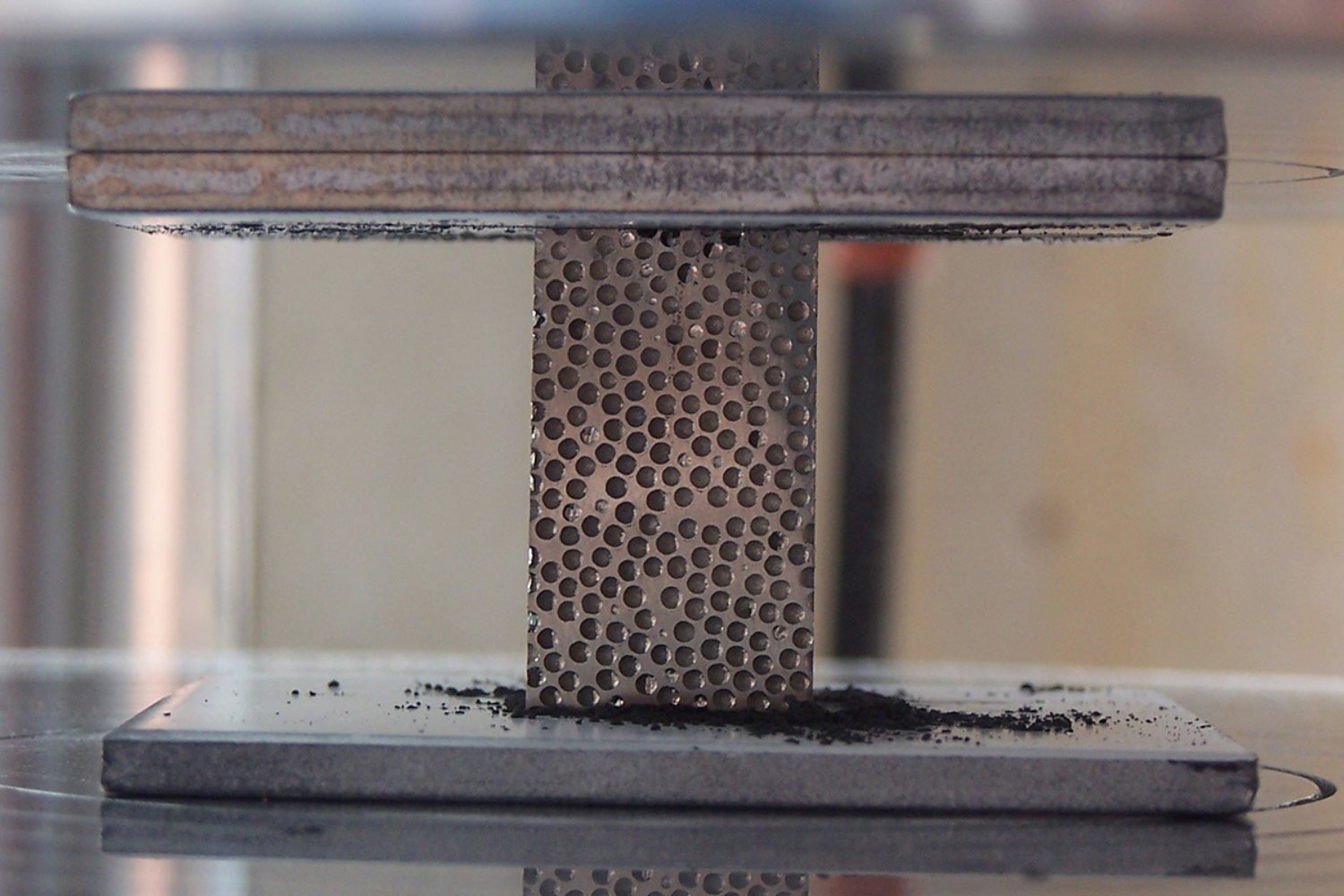

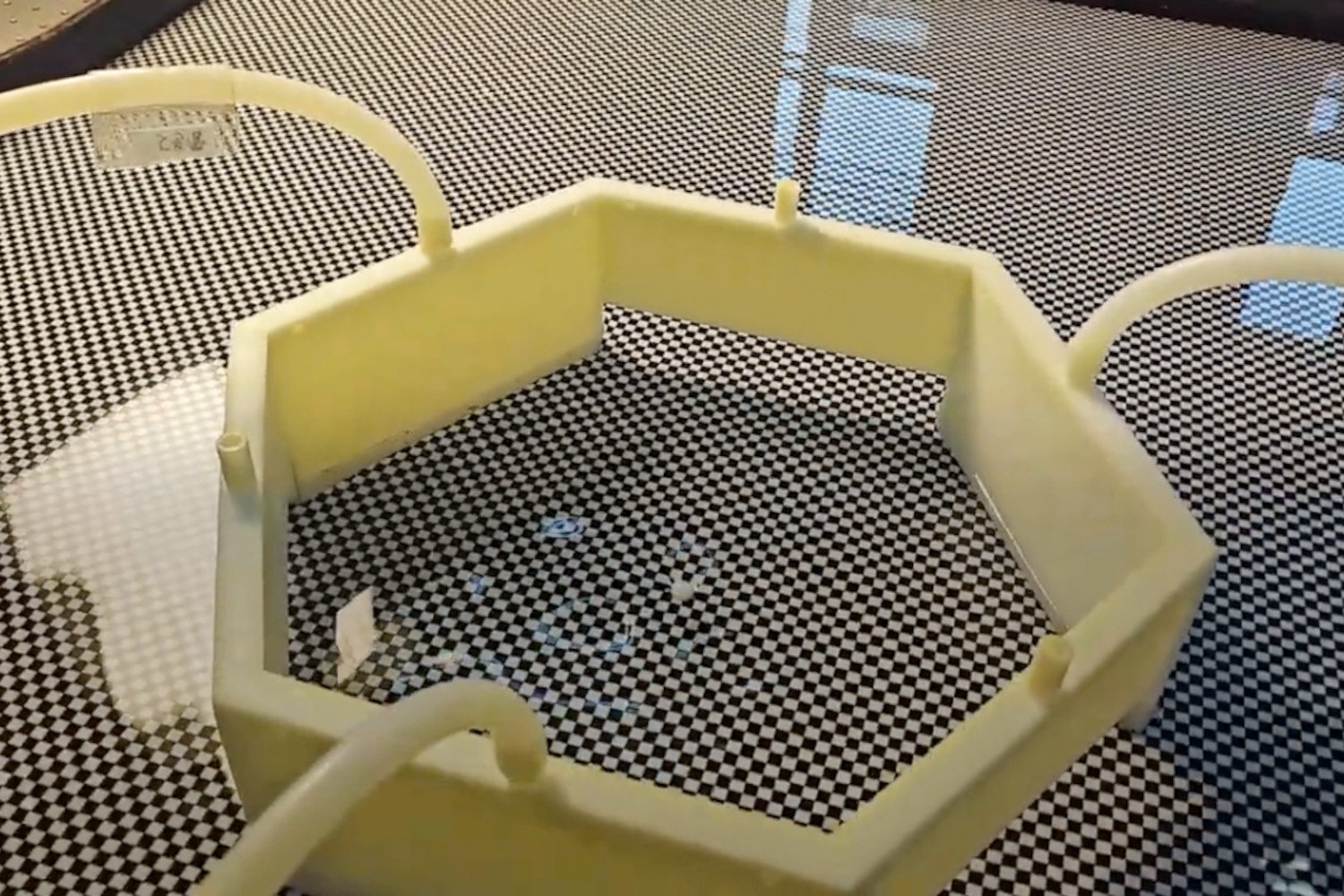

CMF is composed of hollow metallic spheres embedded within a matrix of another metal, such as steel, titanium, or aluminum. This unique structure is the key to its exceptional strength-to-weight ratio. The hollow spheres provide lightweight structural support while the surrounding metal matrix distributes loads and enhances overall strength. After rigorous testing against various threats, including ballistics, blasts, vibrations, radiation, and fire, Rabiei’s company, Advanced Materials Manufacturing, is now ready to bring CMF to market.

Ballistic Protection: Stopping .50 Caliber Rounds

In a 2019 study published in Composite Structures, researchers demonstrated the remarkable ballistic resistance of steel-steel CMF. Vehicle armor constructed using this material proved as effective as conventional steel armor in stopping .50 caliber ball and armor-piercing rounds, yet weighed less than half as much. This significant weight reduction translates to improved vehicle performance and fuel efficiency without compromising protection.

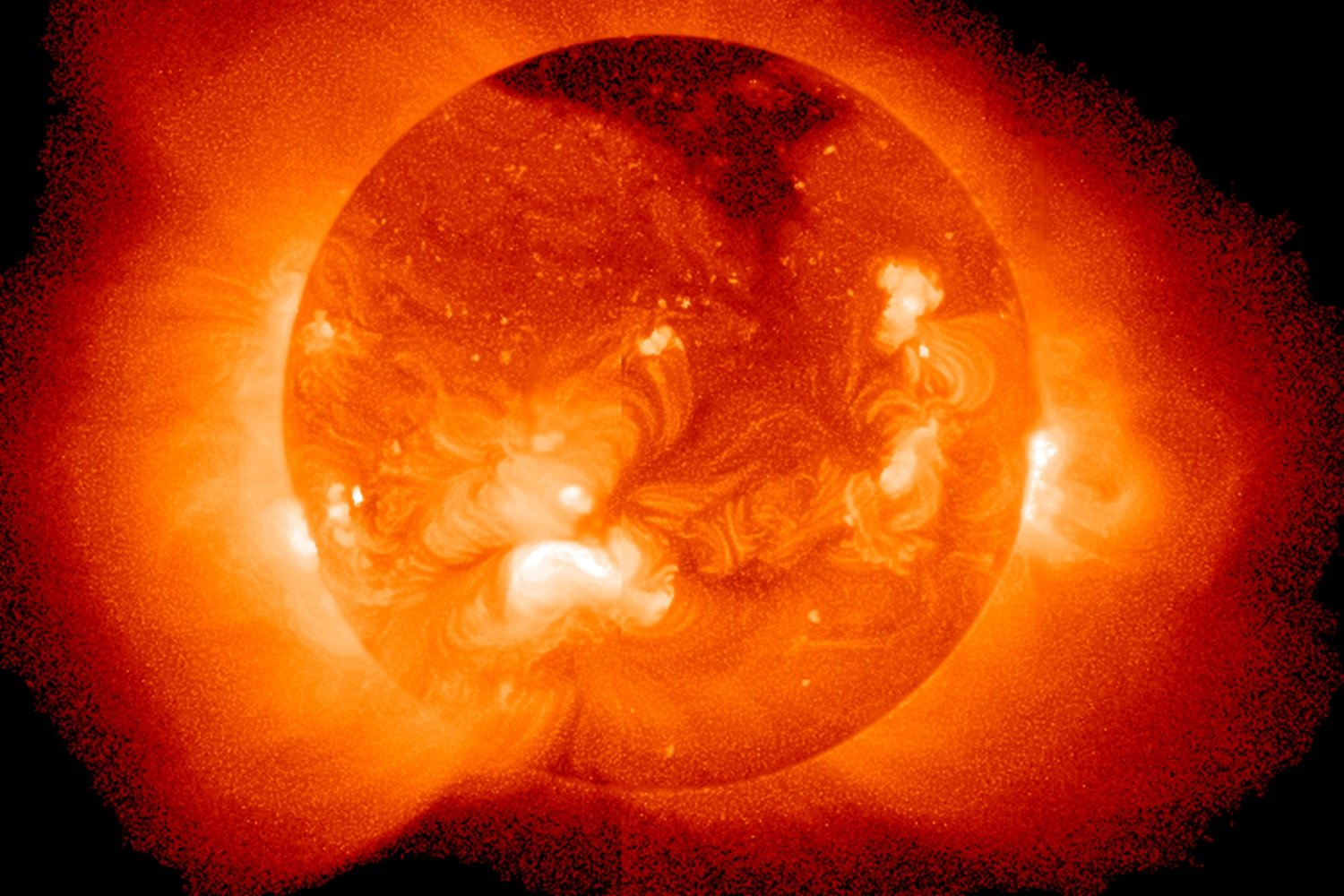

Superior Thermal Insulation: Protecting Against Extreme Heat

CMF also exhibits superior thermal insulation properties. A 2016 study in the International Journal of Thermal Sciences detailed an experiment where both CMF and a solid steel sample were exposed to an 800°C flame. The CMF took twice as long to reach the same temperature as the solid steel, demonstrating its effectiveness in blocking heat transfer. This exceptional insulation is attributed to the air pockets within the CMF structure, which slow down heat propagation. This characteristic makes CMF ideal for protecting heat-sensitive materials, from hazardous chemicals to spacecraft components.

Shielding Against Radiation: From Space to Nuclear Reactors

CMF offers promising capabilities in radiation shielding. A 2015 study in Radiation Physics and Chemistry revealed its effectiveness in blocking X-rays, gamma rays, and neutron radiation. This makes CMF a potential candidate for applications in diverse fields, including space exploration, nuclear waste transportation, and nuclear reactor safety.

CMF: A Modern Marvel with Ancient Parallels

Like the ancient Romans who improved upon existing inventions, CMF enhances the performance of traditional materials by achieving similar or superior results with less weight. While widespread adoption depends on manufacturers embracing this new technology, CMF’s potential to revolutionize multiple industries is undeniable.

Conclusion: A Material with a Bright Future

CMF presents a remarkable combination of strength, lightness, and protective properties. Its potential applications span a wide range of industries, offering solutions for challenges involving ballistic protection, thermal insulation, and radiation shielding. As Advanced Materials Manufacturing moves into production, CMF is poised to become a key material in future technological advancements.