SpinLaunch, a California-based space startup, recently achieved a significant milestone in its mission to catapult payloads into orbit. The company successfully spun a small, modified satellite at 10,000Gs in a lab setting, demonstrating the spacecraft’s ability to withstand extreme gravitational forces. This test reinforces SpinLaunch’s innovative approach to low-Earth orbit (LEO) satellite deployment using a centrifugal launch system.

This demonstration offers valuable insights for potential launch customers, showcasing how satellites can be designed to endure the rigors of SpinLaunch’s unique system. As Sev Sandomirsky, SpinLaunch’s director of satellite programs, explained, the test provides a practical engineering case study and addresses the key question of building SpinLaunch-compatible satellites. It lays the groundwork for developing diverse payloads, encompassing scientific instruments and crucial components for the global economy.

SpinLaunch’s Satellite Modifications for Extreme G-Forces

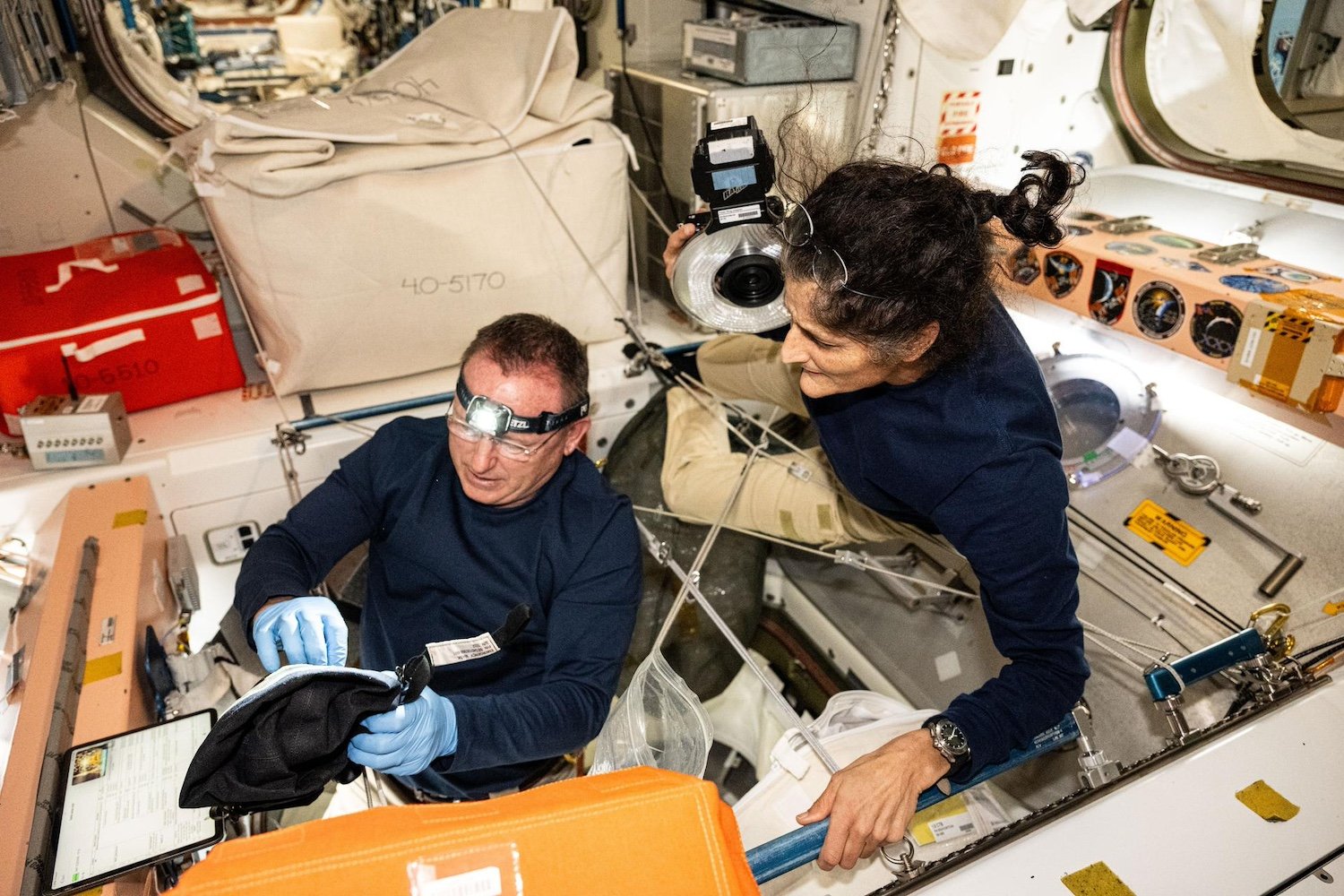

For the test, SpinLaunch collaborated with Portland State University’s OreSat program, utilizing their open-source CubeSat. The SpinLaunch team made several key modifications to enhance the CubeSat’s robustness:

- Battery Cell Reorientation: Battery cells were rotated to function as supporting pillars, bearing their weight along their long axis.

- Adhesive Reinforcement: Glue was applied behind the battery cells for added stability.

- Aluminum Upgrade: The satellite’s structure was upgraded from Aluminum 6061 to the stronger Aluminum 7075.

- Circuit Board Reinforcement: Larger sections of the circuit boards were reinforced to minimize stress on sensitive components.

These modifications, while relatively minor, were crucial for ensuring the satellite’s structural integrity during the high-g test. Sandomirsky highlighted that surprisingly few adjustments were necessary for the 1U CubeSat to survive the 10,000G forces.

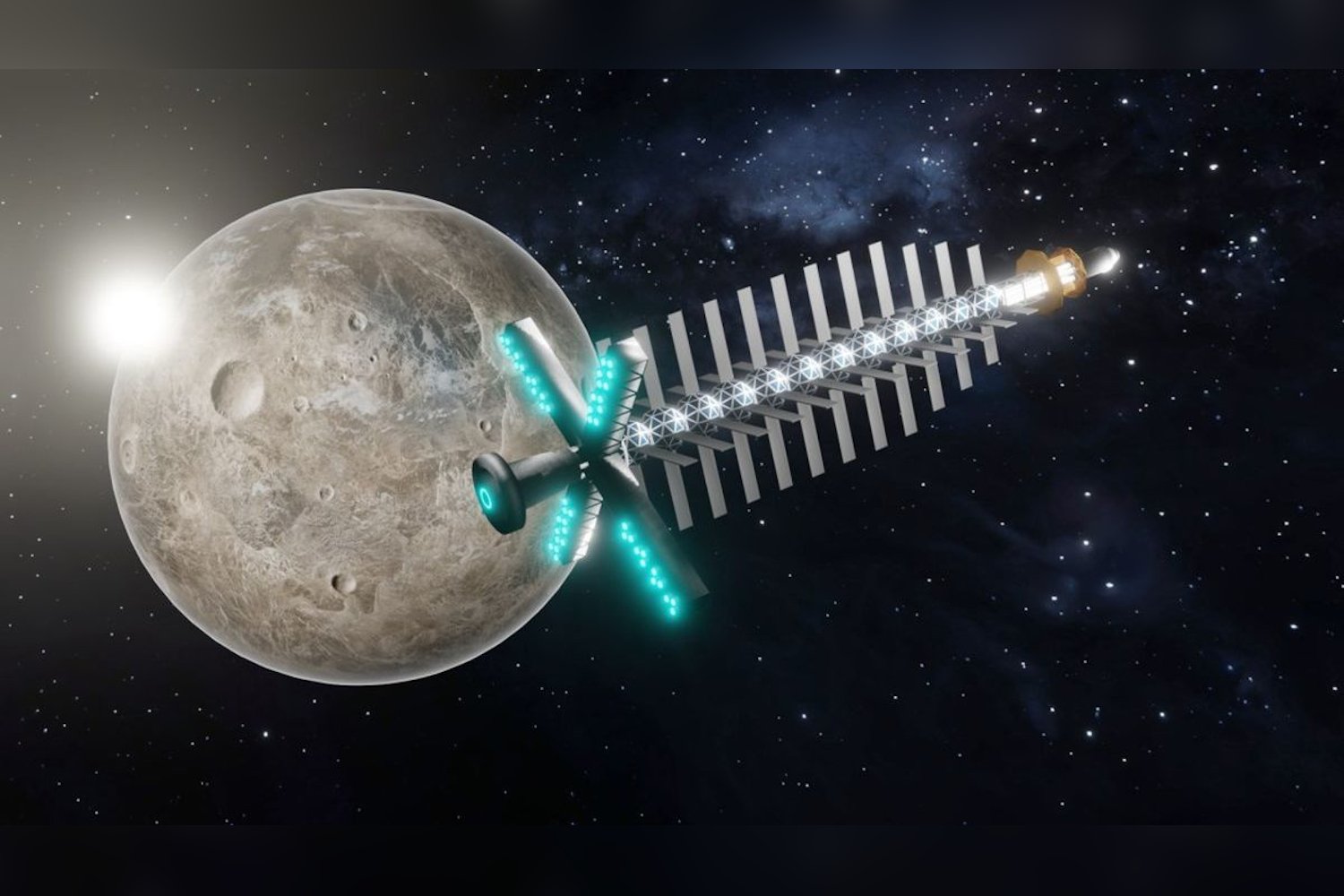

SpinLaunch’s Kinetic Launch System: A Cost-Effective and Eco-Friendly Approach

Founded in 2014, SpinLaunch aims to revolutionize space access with a cost-effective and environmentally friendly kinetic launch system. This system employs a massive centrifuge to propel objects to high altitudes, where a secondary propulsion stage completes the journey to LEO. The company projects a significant reduction in launch costs (up to 90%) and fuel consumption (around 70%) compared to traditional chemical rockets.

SpinLaunch has been steadily progressing towards this vision through tests with its suborbital A-33 accelerator, a 108-foot (33-meter) structure located at Spaceport America in New Mexico. In October 2021, the accelerator, operating at 20% capacity, successfully launched a 10-foot projectile tens of thousands of feet high. A subsequent test in late 2022 involved launching a Test Launch Vehicle carrying payloads for NASA, Airbus, Cornell University, and Outpost Space.

SpinLaunch’s Vision for the Future of Space Access

SpinLaunch CEO David Wrenn emphasizes the potential of their kinetic launch system to reduce costs, increase launch frequency, and promote sustainable space exploration. This technology could also unlock new opportunities for satellite constellations.

A recent funding round secured $11.5 million for SpinLaunch, further supporting the development of its launch system and enabling continued testing of satellite resilience under extreme conditions. The company’s work indicates that many components of modern satellites are already capable of withstanding the high-g environment of a kinetic launch, paving the way for more accessible and efficient space access.

SpinLaunch’s successful 10,000G test demonstrates the viability of its innovative approach and reinforces the potential for a more sustainable and cost-effective future for space exploration.